Application and advantages of LANHI's wet concrete spraying trolley in various engineering construction projects

As an indispensable and important equipment in modern engineering construction, wet concrete spraying trolleys are widely used in mine tunnels, railway and highway tunnels, water conservancy culverts, various underground projects, high-rise building foundation pits, and military projects. Its application in spraying and anchor support operations has greatly improved construction efficiency and safety.

Application fields of LANHI's wet concrete spraying trolleys

1. Mine tunnels: In mining operations, wet concrete spraying trolleys can quickly and effectively support mine tunnels, ensure the safety of operators, and prevent accidents such as landslides.

2. Railway and highway tunnels: Railway and highway tunnel construction requires an efficient support system. The application of wet spraying trolleys not only improves the construction speed, but also ensures the structural stability of the tunnel.

3. Water conservancy culverts: In water conservancy projects, wet spraying trolleys can quickly spray concrete to enhance the waterproof performance and structural strength of culverts.

4. Various underground projects: Whether it is subway construction or underground pipe gallery construction, concrete wet spraying trolleys play an important role in ensuring the quality of the project and the safety of construction workers.

5. High-rise building foundation pit: In the construction of high-rise buildings, foundation pit support is a key link. The wet spraying trolley can spray concrete quickly and evenly to improve the stability of the foundation pit.

6. Military engineering: In the construction of military facilities, the wet spraying trolley is also an indispensable equipment. It can quickly build protective fortifications and improve the concealment and anti-strike capabilities of the project.

Advantages compared to traditional dry spraying machines

Concrete wet spraying trolleys have significant advantages over traditional dry spraying machines. The most prominent feature is that wet spraying operations can significantly reduce dust concentration. Traditional dry spraying machines will generate a lot of dust during operation, which not only affects the construction environment, but also poses a serious threat to the health of construction workers. Wet spraying technology effectively reduces the generation of dust by adding water, improves the construction environment, and protects the health of workers.

In addition, the spraying effect of the wet spraying trolley is more uniform, the concrete adhesion is better, and a tighter support layer can be formed, which improves the overall strength and durability of the support structure.

The importance of LANHI's concrete wet spraying trolley in modern engineering construction cannot be ignored. It not only improves construction efficiency and quality, but also significantly improves the construction environment and protects the health of workers. With the continuous advancement of technology, wet spraying trolleys will play a greater role in more fields and provide more reliable protection for various engineering construction.

Speak with service! Focus on the highlights of LANHI's after-sales inspection!

LANHI2024 "Crossing Mountains and Rivers, Service Accompanying, Satisfied Companion" inspection service has been in full swing for half a month. There is such a group of unknown heroes who leave their warm families and run around in various remote construction sites day and night, not afraid of rugged mountain roads and harsh environments, and provide strong guarantees for the stable operation of customers' equipment.

They are LANHI's service engineers.

Build bridges in communication, find problems in inspections, solve problems in repairs, optimize equipment in maintenance, and improve work efficiency in training. Faced with complex and urgent work tasks, they are not afraid of difficulties, face them head-on, and solve them in time, using professionalism and enthusiasm to escort customers' equipment.

On the construction site with dust and yellow mud, in the complex environment surrounded by mountains and gullies, they are busy with their heads down, focused and determined. They create value with communication, demonstrate skills with efficiency, win recognition with dedication, and win trust with sincerity. Providing customers with full support after-sales service has also won LANHI the respect and trust of customers.

After-sales service is a long journey, and service is on the front line. LANHI's service engineers go all out and persevere. They work day and night, in the wind and rain, and they are down-to-earth and forge ahead.

LANHI's engineering machinery is unique in the field of smart construction

In recent years, LANHI's engineering machinery has made remarkable achievements in the field of smart construction and has become a leader in the industry. Through continuous innovation and research and development, the company has launched a series of efficient and intelligent engineering machinery equipment, including multi-functional tunnel boring machines, intelligent arch-anchor integrated trolleys and intelligent arch frame integrated trolleys, providing strong support for engineering construction.

1. Multi-functional tunnel boring machine: a powerful tool for tunnel construction

The multi-functional tunnel boring machine is a star product of LANHI. It integrates multiple functions in one. It can not only perform tunneling operations, but also complete a variety of complex underground construction tasks. This equipment is equipped with an advanced automatic control system, which can achieve high-precision and high-efficiency tunneling operations. Its strong adaptability and flexibility enable it to perform well under various geological conditions, greatly improving construction efficiency and reducing labor costs.

2. Intelligent arch-anchor integrated trolley: improving construction safety and construction efficiency

The intelligent arch-anchor integrated trolley is a device specially designed by LANHI to improve the safety of tunnel construction. The trolley integrates arch frame installation and anchor construction, and can automatically complete the positioning and installation of the arch frame and the drilling and installation of the anchor. The application of the intelligent control system not only improves the construction speed, but also ensures the accuracy and safety of the construction. Especially in complex geological environments, the advantages of the intelligent arch-anchor integrated trolley are more obvious, effectively reducing the construction risk.

3. Intelligent arch frame integrated trolley: improve construction safety and construction efficiency

The intelligent arch frame integrated trolley is another innovative equipment launched by LANHI to further improve the efficiency of tunnel construction. The trolley can automatically complete the assembly and installation process of the arch frame, reducing the tedious steps of manual operation. The intelligent operating system enables it to operate flexibly in a small construction space, significantly improving the overall efficiency of construction. The intelligent arch frame integrated trolley not only saves time, but also reduces construction costs. It is an indispensable tool for modern tunnel construction.

LANHI's engineering machinery has taken the lead in the field of smart construction through continuous technological innovation and product upgrades. Its multifunctional tunnel boring machine, intelligent arch-anchor integrated trolley and intelligent arch frame integrated trolley have not only greatly improved construction efficiency and safety, but also led the industry's intelligent development direction. In the future, LANHI will continue to uphold the spirit of innovation and continuously launch more efficient and intelligent construction equipment to help smart construction reach a new level.

2024 Moscow Engineering and Mining Machinery Exhibition: LANHI's Tunnel Engineering Products Attract Attention

The 25th Russia International Construction and Engineering Machinery Exhibition (CTT-EXPO) in 2024 was grandly held at the Crocus Exhibition Center in Moscow. This exhibition is one of the most significant and influential industry events in Russia and the CIS countries, attracting numerous internationally renowned companies and professional visitors. Among the many exhibitors, LANHI stood out with its innovative tunnel engineering products, becoming a highlight of the exhibition and garnering widespread attention from within and outside the industry.

LANHI's tunnel engineering products are characterized by their high efficiency and intelligence, meeting the demands for efficiency and safety in modern tunnel engineering machinery. These products not only excel in performance but also offer more intelligent operations, providing a solid guarantee for the automation and intelligent development of tunnel engineering. Through continuous technological innovation and R&D investment, LANHI has demonstrated its strong capability and competitiveness in tunnel engineering machinery.

Exhibition Overview

The Russian Mining and Engineering Machinery Exhibition, MINING WORLD RUSSIA, annually showcases the most advanced mining equipment and technology, being regarded as a barometer of industry development. This year's exhibition not only displayed advanced mining machinery and related equipment from around the world but also covered the latest technologies and products in various fields of engineering machinery. The wide range of exhibits included excavation machinery, rock drilling machinery and mining machinery, rebar and prestressing machinery, pneumatic tools, concrete machinery, decoration machinery, electric tools, pile driving machinery, sanitation machinery, motorized industrial vehicles, power devices and accessories, various accessories and electrical components and assemblies, and testing engineering machinery parts, providing visitors with a one-stop procurement platform.

The exhibition provided an excellent platform for industry practitioners, allowing them to learn about the latest technologies and products and engage in face-to-face exchanges and cooperation. Whether for purchasing equipment or technical consultations, visitors could find everything they needed here. During the exhibition, major companies showcased their latest products and technologies, promoted their brands, and expanded their businesses, further driving the industry's development and progress.

The 2024 Moscow Engineering and Mining Machinery Exhibition not only displayed the latest achievements in the industry but also pointed out the direction for future development. LANHI, with its leading technology and products, became the focus of this exhibition, setting a new benchmark for the intelligent development of tunnel engineering machinery.

Armored Machinery fight fiercely in Zhen-Guang-LANHI helps Zhen-Guang Expressway to make progress on multiple projects

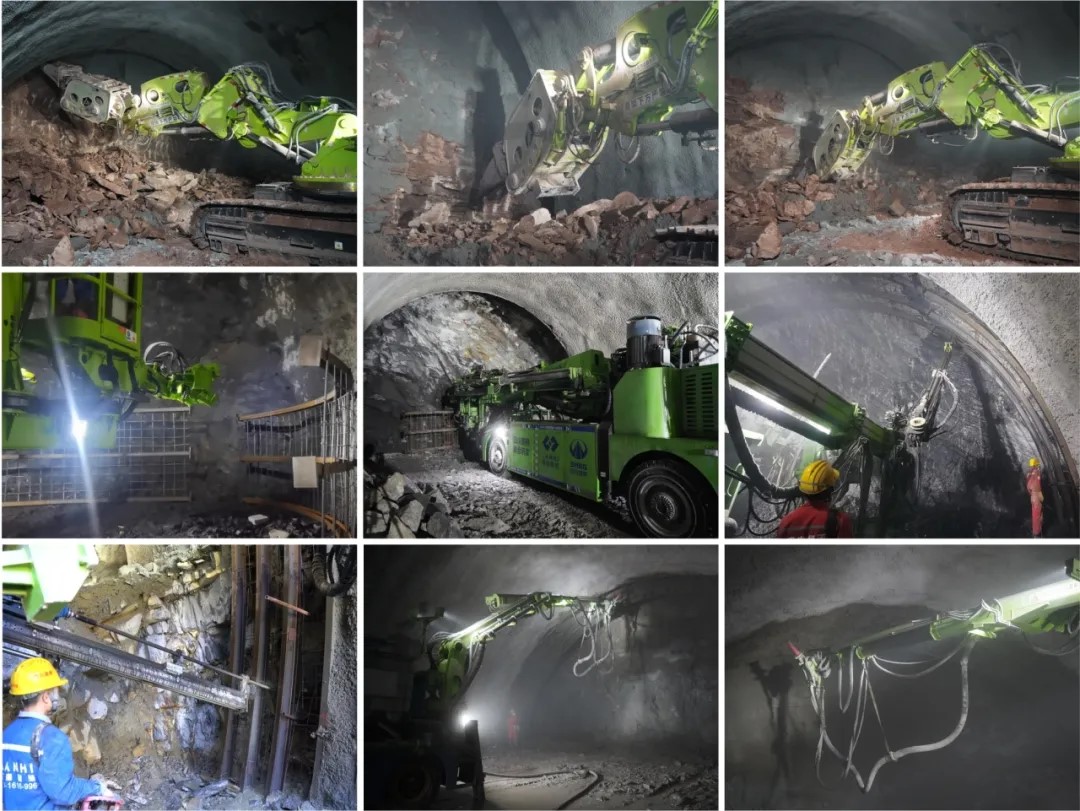

Spring brings vitality, and with it, significant progress in various construction sites of the provincial key project, Zhen Guang Expressway. LANHI’s "Iron Armored Soldiers" are demonstrating their strength and pioneering spirit, driving major advancements in multiple tunnel projects and creating a dynamic and efficient construction blueprint.

1、Pingchang Tunnel

As a pilot project for fully mechanized equipment construction, the Pingchang Tunnel stretches 5,600 meters and is a long, low-gas tunnel. With a lengthy construction period, poor geological conditions, and high safety risks, LANHI has provided six intelligent pieces of equipment for this project. These include the LG312M intelligent arch installation vehicles and 40F wet spraying manipulators, fully implementing the concept of "mechanization reduces labor, automation replaces labor" by Shudao Group. This has effectively reduced construction safety risks and the number of workers in the tunnel face, significantly improving construction quality and efficiency.

At the beginning of this year, the Pingchang Tunnel, a key project in the C3 section of the Tongguang segment, successfully surpassed the 2,000-meter mark in its advancement.

2、Baiyi No. 2 Tunnel

The Baiyi No. 2 Tunnel project is a control project from Yuejia Town to Hanshui Town on the Zhen Guang Expressway. With significant construction difficulty, LANHI’s multifunctional tunneling machine was brought in for non-explosive mechanical excavation, wireless remote control operation, minimal surrounding rock disturbance, high intelligence, low dust, and the ability for two workers to complete the excavation. This has effectively reduced construction safety risks and the number of workers.

At the C6 section of the Baiyi No. 2 Tunnel construction site, workers are remotely operating LANHI's multifunctional tunneling machine, pushing forward with the tunneling work vigorously.

3、Guangna Tunnel

The Guangna Tunnel, with a length of 3,426 meters, consists mainly of siltstone and sandstone and has surrounding rock grades of IV and V. It is the only high-gas tunnel along the entire route, facing high risks such as high gas, shallow burial, landslides, water inrush, and crossing under a reservoir. LANHI’s LG312M intelligent arch installation vehicles were brought in to support mechanized operations, enhancing safety at the tunnel face, accelerating construction progress, and reducing labor costs, laying a solid foundation for early completion.

Currently, the Guangna Tunnel in the C1 section of the Tongguang segment has achieved a cumulative bi-directional advance of over 3,000 meters.

4、Ranjiaba Tunnel

The right line of the Ranjiaba Tunnel is 1,736 meters long, and the left line is 1,743 meters long, located in Tiexi Town, Tongjiang County. It is a low-gas tunnel with surrounding rock grades of IV and V. The entrance location is steep and has a large height difference. LANHI’s LG312M intelligent arch installation vehicles have been deployed to ensure smooth tunnel entrance construction.

In mid-April, the right entrance of the Ranjiaba Tunnel in the B2 project of the Chuanwang segment successfully entered, marking another acceleration in the construction of the B2 project.

To date, LANHI has continuously supported the construction of over 20 tunnels on the Zhen Guang Expressway, deploying more than 30 intelligent pieces of equipment, including multifunctional tunneling machines, intelligent arch/anchor installation vehicles, and wet spraying manipulators. Moving forward, LANHI will continue to support mechanized construction and lead with intelligent operations, further promoting the integration of innovative technologies and construction practices, aiding in the completion and operational efficiency of the entire Zhen Guang Expressway by 2026, thus empowering high-quality economic development.

Five Significant Advantages of the Blue Ocean Intelligent Integrated Arch-Anchor-Spray Vehicle in Modern Tunnel Construction

In modern tunnel construction, the Blue Ocean Intelligent Integrated Arch-Anchor-Spray Vehicle has brought revolutionary advancements to engineering teams, significantly enhancing construction efficiency and safety. Here are the five notable advantages this equipment offers for tunnel construction:

1、Dual Safety Assurance

The Blue Ocean Intelligent Integrated Arch-Anchor-Spray Vehicle is designed with a strong emphasis on operator safety. Firstly, the vehicle utilizes multiple prefabricated arch frames to ensure that operators are always protected by the arch structure. Secondly, during the spraying and anchor bolt installation phases, personnel are situated within the safeguarded surrounding rock, effectively reducing safety risks during construction.

2、Efficient Arch Installation: Completed in One Hour

This equipment can complete the installation and positioning adjustments of prefabricated arch frames within an hour, accommodating various step construction methods. Whether dealing with complex installation processes or precise positioning adjustments, the tasks can be efficiently completed in a short time, greatly shortening the construction cycle.

3、Significant Reduction in Equipment Costs

The Blue Ocean Intelligent Integrated Arch-Anchor-Spray Vehicle combines the functions of a wet spraying vehicle, arch installation vehicle, anchor bolt vehicle, and grouting machine into one. Compared to traditional tunnel construction equipment, this integration can save millions in procurement costs. This multifunctional design reduces the number of equipment purchases needed, lowering overall investment.

4、Halved Personnel and Time Costs

By utilizing this vehicle, the entire initial support process requires only five operators and can be completed within six hours. Specifically, three people handle arch installation and system anchor bolt work, while two are responsible for spraying operations. In contrast, traditional operations would require at least 12 workers to complete the same task in 12 hours. This efficiency can save hundreds of thousands of yuan in labor costs annually.

5、Cloud Data Management

The Blue Ocean Intelligent Integrated Arch-Anchor-Spray Vehicle is equipped with an advanced cloud management system, enabling visualization and data management of the construction process. Construction data is transmitted in real-time via an app, making it easy to view equipment positioning, on-site conditions, equipment monitoring, and hazard identification. Additionally, it supports remote monitoring and command synchronization, ensuring real-time monitoring and management of the construction process.

The Blue Ocean Intelligent Integrated Arch-Anchor-Spray Vehicle excels in enhancing tunnel construction efficiency and safety. It not only reduces equipment and labor costs but also provides comprehensive protection for the construction process through cloud data management. This innovative equipment undoubtedly offers significant advantages for modern tunnel construction.

Multifunctional Applications of Arch Installation Trolleys in Tunnel Construction

The arch installation trolley is a multifunctional piece of construction equipment that plays a crucial role in tunnel construction. This equipment not only improves construction efficiency but also enhances safety. Here are the main functions of the arch installation trolley in tunnel construction.

1. Steel Frame Installation

One of the primary functions of the arch installation trolley is to install steel frames inside tunnels. The steel frame acts as the skeleton of the tunnel structure, supporting its stability and safety. By using the installation trolley, the steel frames can be accurately positioned and quickly installed, increasing work efficiency and installation precision.

2. Mesh Installation

In addition to steel frames, the arch installation trolley is also used for installing mesh. The mesh is part of the tunnel lining, used to distribute and absorb ground stress, preventing rock loosening and collapse. The installation trolley can carry and secure the mesh, allowing it to be installed quickly and accurately.

3. Connecting Bar Installation

Connecting bars are crucial components between steel frames and mesh, ensuring the integrity and stability of the entire support structure. The arch installation trolley assists in the installation of connecting bars, ensuring each connection point is firm and reliable.

4. Assisting in Inspection and Hazard Mitigation

Safety inspections and hazard mitigation are vital during tunnel construction. The arch installation trolley is equipped with relevant devices and tools, assisting construction personnel in conducting safety inspections and hazard mitigation work, promptly identifying and addressing potential dangers to ensure construction safety.

5. Under-excavation Handling

During tunnel excavation, under-excavation may occur, where the actual excavation size is smaller than the design size. The arch installation trolley can assist construction personnel in handling under-excavation, ensuring the tunnel cross-section meets design requirements.

6. Explosive Installation

In tunnel construction requiring blasting operations, the installation of explosives is a critical step. The arch installation trolley is equipped with safety protection devices and operation platforms, aiding construction personnel in safely and accurately installing explosives, ensuring the safety and effectiveness of blasting operations.

7. Rock Bolt Installation

Rock bolts are a crucial part of tunnel support, used to stabilize the surrounding rock and prevent collapses. The arch installation trolley can carry rock bolts and installation equipment, assisting construction personnel in installing rock bolts, thereby improving construction efficiency and safety.

The arch installation trolley integrates several key processes in tunnel construction. Its multifunctional applications significantly enhance construction efficiency, quality, and safety. The widespread use of this equipment provides solid support for tunnel construction.

LanHi Smart Multi-Function Tunneling Machine: Non-Blasting Excavation for Various Working Conditions

The LanHi Smart Multi-Function Tunneling Machine is an advanced piece of equipment specifically designed for non-blasting excavation. It integrates multiple innovative technologies aimed at achieving efficient, safe, and environmentally friendly underground construction. The main features of this equipment include its multifunctionality, precision, and adaptability to complex geological conditions.

1、Multifunctionality:

The Blue Ocean Smart Multi-Function Tunneling Machine can be operated via both local control and wireless remote control, making it suitable for tunnel excavations ranging from 6 to 9.5 meters in diameter. It combines high-frequency rock breaking, rapid soft soil excavation, contour trimming, and dust suppression through spraying into one machine. It is ideal for construction in areas where blasting is restricted, such as airports, residential areas, and wildlife protection zones. Its strong adaptability meets the requirements of various surrounding rock constructions, reducing instances of over-excavation and collapses.

2、Precision:

This equipment employs advanced navigation and positioning systems to ensure precise control during the construction process. By continuously monitoring the construction environment and equipment status in real-time, it can accurately adjust the tunneling direction and speed, ensuring construction quality and safety.

3、Adaptability to Complex Geological Conditions:

The Blue Ocean Smart Multi-Function Tunneling Machine is particularly suited for work in complex geological conditions, such as hard rock, soft soil, and high water content layers. Its powerful rock-breaking capability and adaptability enable effective construction in various harsh environments.

4、Safety:

By utilizing a non-blasting excavation method, this equipment significantly reduces the risks at the construction site. Non-blasting operations minimize the impact on the surrounding environment, protecting the safety of construction personnel and reducing potential damage to nearby buildings and facilities.

5、Environmental Friendliness:

Non-blasting excavation reduces environmental pollution by avoiding issues such as vibrations, noise, and flying debris caused by blasting. Additionally, the energy-efficient design of the equipment helps to lower energy consumption, further enhancing its environmental performance.

The development and application of the Blue Ocean Smart Multi-Function Tunneling Machine represent a new direction in underground construction technology. It offers innovative solutions for urban construction, transportation infrastructure, and resource extraction, promoting advancements in underground engineering techniques.

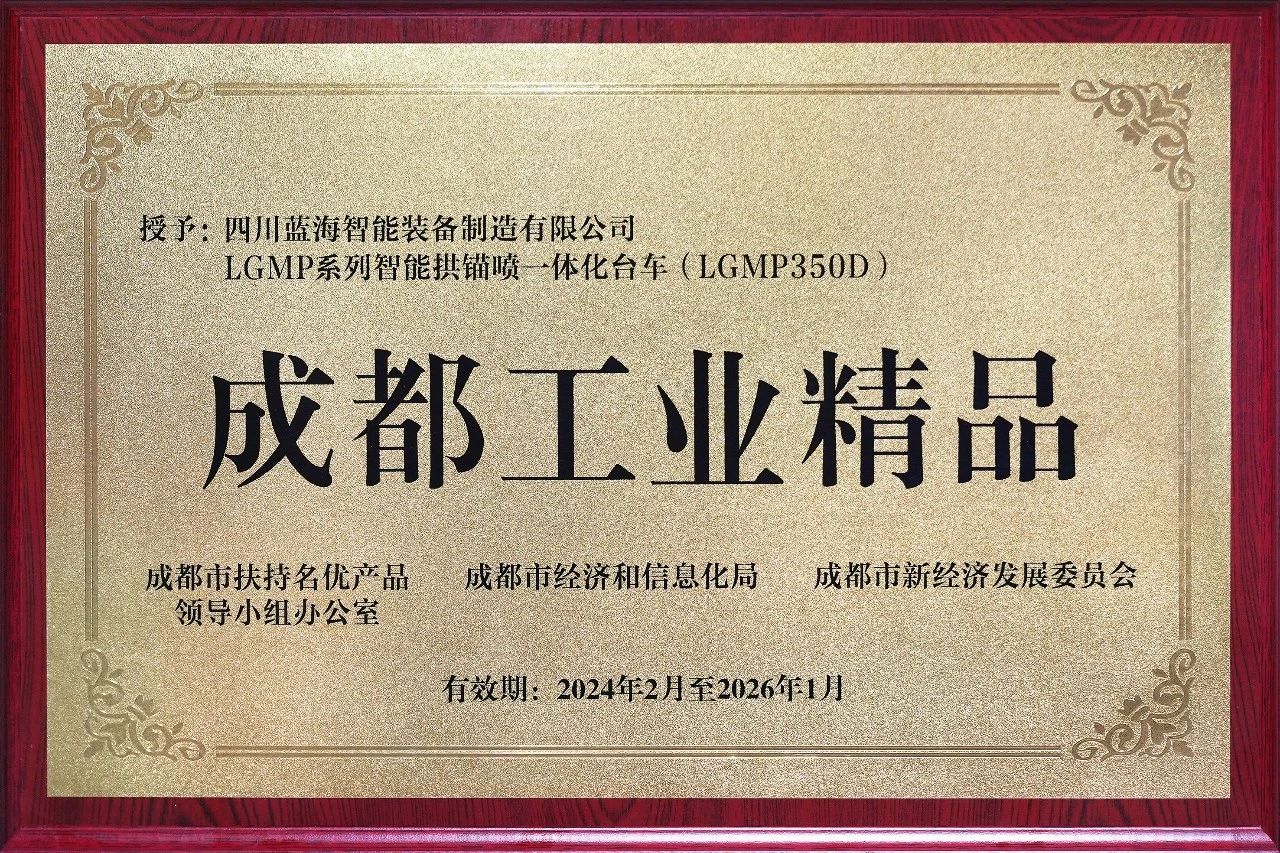

LanHi Intelligent Arch Anchor Spraying Trolley Honored with Chengdu Industrial Quality Award

At the end of February 2024, the "Chengdu Made" supply and demand docking event and the Chengdu Industrial Quality Award ceremony were successfully held. This event was guided by the Chengdu Municipal Leading Group for Supporting Famous and Excellent Products and organized by the Chengdu Economic and Information Bureau's New Economy Development Committee (Chengdu Municipal Leading Group for Supporting Famous and Excellent Products Office). At the event, the Blue Ocean Intelligent LGMP350D Integrated Trolley for Arch Anchor Spraying, after rigorous selection, was honored with the title of "Chengdu Industrial Quality" and officially launched globally as a new calling card for "Chengdu Manufacturing."

According to the organizers, the establishment of the "Chengdu Industrial Quality" brand and the creation of a high-level platform for supply and demand docking are innovative carriers to implement the manufacturing strong city strategy of the Municipal Party Committee and Government and the decision to implement the "Chengdu Manufacturing Brand." This initiative aims to implement the "Three-Quality" action plan in manufacturing, deepen the expansion of scenario applications, cultivate international influence, and enhance the city (industry) brand and Chengdu's visibility.

The Blue Ocean Intelligent LGMP350D Integrated Trolley for Arch Anchor Spraying, which was honored with the "Chengdu Industrial Quality" award, is the first set of products in Sichuan Province. It integrates the functions of wet spraying Trolley, arch frame installation Trolley, and anchor rod Trolley into one, enabling integrated construction of tunnel initial support operations.

The equipment can independently complete the entire process of tunnel initial support, including erection, anchoring, foot locking, advance spraying, etc., with erection taking about 1 hour. The three arms are fully sliding, capable of meeting various types of arch frame installations, various step method operations, and precise adjustment of arch frame positioning. Compared to traditional equipment, it is more convenient in construction, reduces equipment relocation time, has a wider range of applications, and higher mechanization degree, resulting in significant savings in labor, time, and money, as well as improved safety. It can also be equipped with a mobile APP intelligent management platform for efficient management and dual breakthroughs in safety control.

The receipt of the "Chengdu Industrial Quality" honor is not only a recognition of the quality of Blue Ocean products but also an affirmation of Blue Ocean's strategy of adhering to technological innovation to lead development. In the future, we will continue to increase research and development investment, fully enhance the brand value of "Chengdu Industrial Quality," and help "Chengdu Manufacturing" go global. At the same time, we will comprehensively improve our company's product production and delivery capabilities, promote a substantial increase in enterprise output value, create more value for underground engineering digitization construction, and contribute more to accelerating the construction of a manufacturing powerhouse.

Upgraded LG312M Intelligent Arch Frame Trolley - Construction Made More Flexible!

Since the launch of the new upgraded "lightweight" LG312M intelligent arch frame integrated trolley by LanHi Installation, it has received widespread acclaim and has been continuously used in tunnel construction projects across the country.

This intelligent arch frame integrated trolley integrates multiple processes, including measurement, excavation, arch frame installation, welding of mesh and connecting bars, etc., with features of fast, efficient, energy-saving, and safe operation. It has been upgraded in appearance, weight, and boom, bringing a brand-new flexible experience to tunnel construction.

The new generation of LG312M intelligent arch frame trolley has the following features:

1. Lightweight design: 20% reduction in weight, smaller dimensions, making construction more flexible, capable of completing the excavation and arch frame installation of double-line tunnels without relocating the machine.

2. High-level boom: Utilizing a design of three arms, three grippers, and three baskets, making construction more convenient, effectively reducing construction time, and improving construction efficiency.

3. Extendable baskets: Increasing operating space for baskets, facilitating the loading of explosives and anchor rods, enhancing construction safety.

This trolley not only saves time and effort but also has high safety, able to adapt to various complex tunnel conditions, serving as an intelligent and efficient construction tool. In practical applications, it has been successfully used in multiple engineering projects such as Chengnan Expressway Expansion, Hydropower VII Bureau Bara Hydropower Station, Plateau Railway, and Jiuma Expressway, providing customers with fast, accurate, and flexible mechanized arching services.

In the future, Blue Sea Smart Installation will continue to adhere to the goal of replacing manpower with machines and intelligent construction, continuously advancing the intelligent upgrading of products, helping to continuously improve the quality of tunnel engineering, and creating greater value for customers.