Open rock tunnel boring machine (abbreviated as open TBM) is an important equipment in modern tunnel construction, which is specially used for rock tunnel excavation projects with good rock stability and less weak surrounding rock. Under geological conditions with high stratum integrity and high uniaxial compressive strength, this equipment shows extremely high construction efficiency and cost-effectiveness, becoming a popular choice in the engineering industry.

Structural composition of open TBM

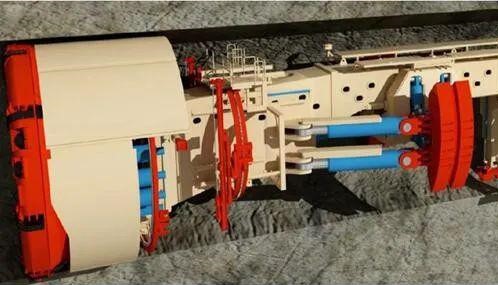

The main structure of open TBM is complex and precise, mainly composed of the following key parts:

1. Cutterhead: responsible for cutting rock, it is the core component of TBM. The cutterhead cuts the rock in front through rotational motion, allowing the tunnel to move forward continuously.

2. Drive system: provides power to drive the cutterhead to rotate and ensure the normal operation of the equipment.

3. Shield: located behind the cutterhead, protects the equipment and operators from rock collapse.

4. Main beam: connects and supports all parts of the entire equipment, providing structural stability.

5. Saddle: provides support and positioning for the cutterhead and drive system to ensure cutting accuracy.

6. Shoes: provide additional stability and support, especially during excavation.

7. Rear support: support and fix the tail of the tunnel boring machine to maintain overall balance.

Scope of application and advantages

Open TBM is particularly suitable for strata with good rock integrity and high uniaxial compressive strength. These strata usually have the following characteristics:

- Good rock stability: The rock strata are strong and not easy to collapse, and the risk during excavation is low.

- Less weak surrounding rock: There are fewer weak surrounding rocks encountered during excavation, and the construction difficulty is relatively low.

Under such geological conditions, open TBM can play its greatest advantages:

1. High construction efficiency: Due to good stratum conditions, the excavation speed is fast and the construction period is greatly shortened.

2. Low cost: The equipment maintenance and operation costs are low, and the economic benefits are significant.

With its high efficiency and low cost, the open rock tunnel boring machine has become the best choice for tunnel excavation under suitable geological conditions. Its wide application not only improves construction efficiency, but also effectively reduces engineering costs, making an important contribution to the tunnel construction industry.