As an important equipment in tunnel construction, the secondary lining trolley is mainly used for concrete pouring of tunnel secondary lining. Its working principle combines mechanical automation and concrete pouring technology to achieve efficient and precise construction of tunnel lining. Below, we will discuss the construction process of the secondary lining trolley in detail.

The construction process of the secondary lining trolley is as follows:

1. Trolley positioning: Move the trolley to the position where lining is required, and adjust the trolley to the correct height and horizontal position through devices such as jacks.

2. Template positioning: Adjust the template of the trolley to the position and shape required by the design through devices such as hydraulic systems or screws to ensure that the template fits tightly with the tunnel wall.

3. Concrete pouring: Pour concrete in the template, and the concrete can be transported into the template by pumping or other means. During the pouring process, attention should be paid to the uniformity and density of the concrete to avoid quality problems such as voids or honeycombs.

4. Vibration and curing: After the concrete is poured, a vibrator is needed to vibrate the concrete to ensure the compactness of the concrete. At the same time, the concrete needs to be cured to ensure the strength and durability of the concrete.

5. Demolding and moving: After the concrete reaches a certain strength, the formwork of the trolley needs to be removed, and then the trolley is moved to the next location where lining is required for the next lining construction.

The secondary lining trolley realizes the automated construction of the secondary lining of the tunnel through its precise structural design and control system, greatly improving the construction efficiency and engineering quality.

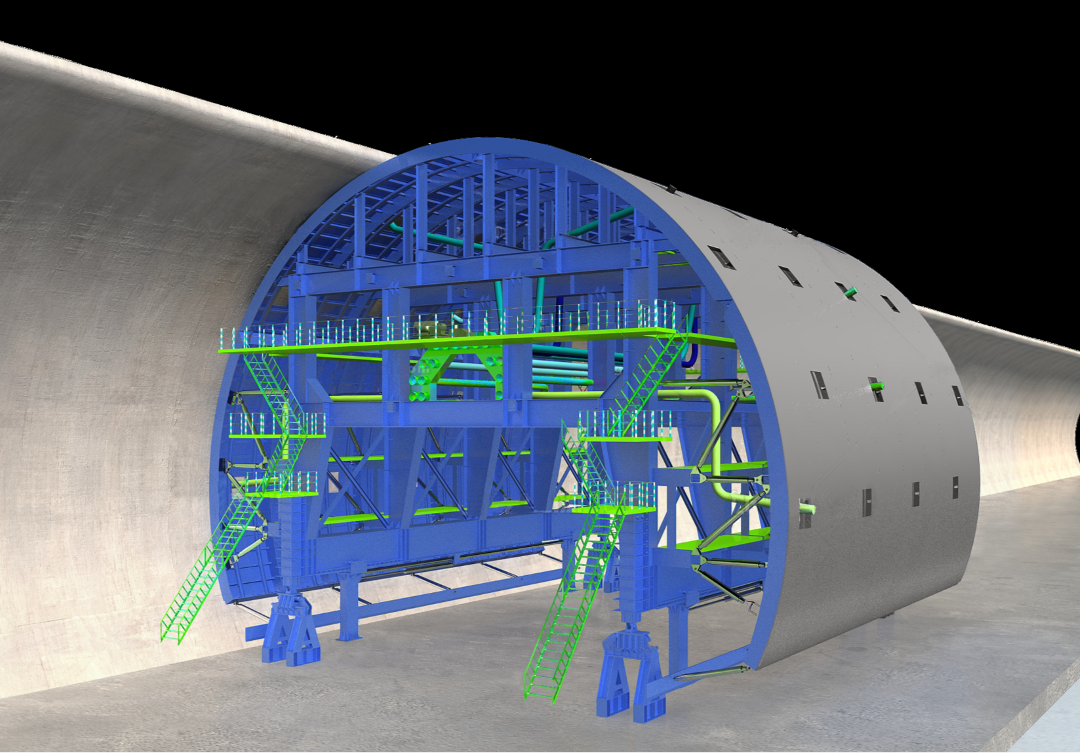

The secondary lining trolley is mainly composed of a traveling mechanism, a template system, a concrete pouring system, a hydraulic system, an electrical control system, etc. Among them, the traveling mechanism is used for the movement of the trolley in the tunnel; the template system is responsible for forming the mold for concrete pouring; the concrete pouring system is used for the transportation and pouring of concrete; the hydraulic system and the electrical control system are used to control the operation of the trolley and the opening and closing of the template.