As a key equipment in modern tunnel construction, the flexibility of design and application of TBM has greatly improved the efficiency and safety of tunnel construction. The diversified classification of TBM reflects its ability to adapt to different geological conditions and engineering needs. This paper will discuss the classification of TBM from four aspects: cutterhead shape, excavation section shape, working rock hardness and relationship with the tunnel wall, in order to provide reference for engineering design and construction.

1. Different classifications according to cutterhead shape

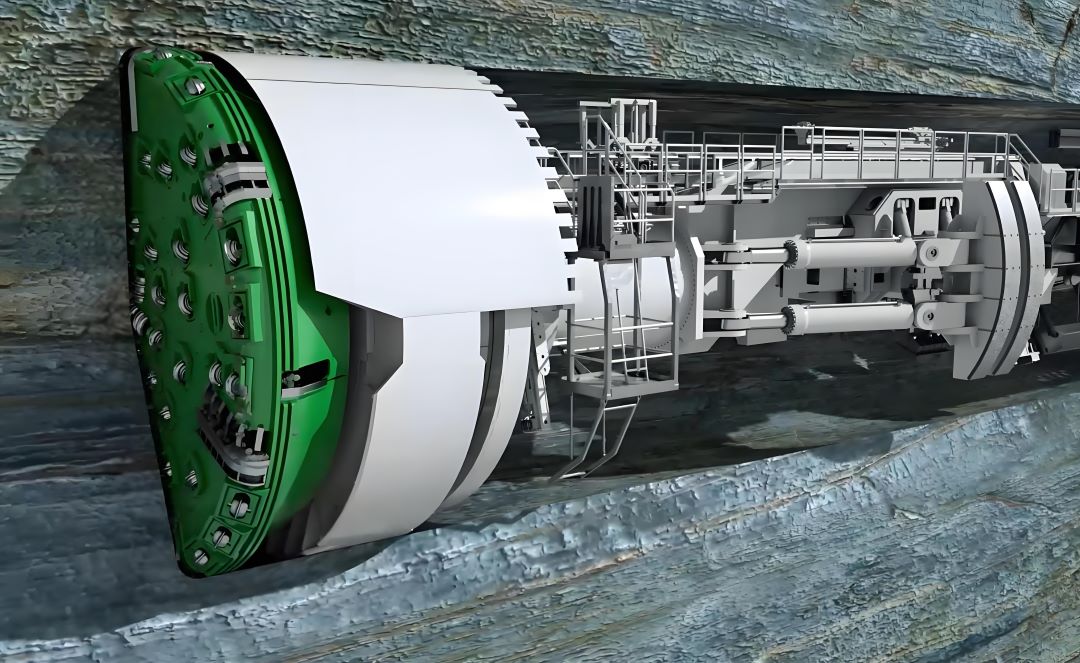

The cutterhead shape of TBM is an important dimension in its classification. Flat cutterhead TBM is the most common type at present, suitable for a variety of geological conditions, with simple design and flexible operation. Spherical cutterhead TBM and conical cutterhead TBM respectively improve the cutting efficiency and stability in specific geological environments through their unique geometric shapes. These cutterhead designs of different shapes enable TBM to operate efficiently in rocks of different hardness, ensuring the continuity and safety of tunnel excavation.

2. Different classifications according to excavation section shape

The shape of the excavation section directly affects the structural design and construction cost of the tunnel. The circular cross-section full-section TBM is the most widely used type at present. Its advantage is that it can form a stable circular cross-section, which is convenient for subsequent lining operations and is also conducive to groundwater management. The non-circular cross-section full-section TBM can meet the needs of special projects. For example, the rectangular cross-section is suitable for the development of urban underground space, which can make more effective use of underground space and reduce the impact on ground buildings.

3. Different classifications according to the hardness of the operating rock

According to the hardness of the operating rock, TBM is divided into soft rock, medium hard rock and hard rock full-section TBM. Soft rock full-section TBM is suitable for geological environments with a uniaxial compressive strength of less than 100MPa, medium hard rock full-section TBM is suitable for rocks with a uniaxial compressive strength of less than 150MPa, and hard rock full-section TBM can cope with rock hardness up to 350MPa, reflecting the adaptability and flexibility of TBM under different geological conditions.

4. Classification by the relationship between the full-face TBM and the tunnel wall

Open full-face TBM and shield full-face TBM are the two main classifications. When the open full-face TBM is operating, there is no additional protective structure between the TBM and the tunnel wall, which is suitable for relatively stable geological conditions. The shield full-face TBM protects the TBM and construction personnel by setting up a shield. It is suitable for complex and unstable geological conditions. It is further subdivided into single-shield, double-shield and triple-shield full-face TBMs to meet the needs of different projects.

Full-face TBMs can be classified in various ways, and each classification reflects its application advantages in a specific engineering environment. By reasonably selecting and applying different types of TBMs, the efficiency of tunnel construction can be effectively improved and construction risks can be reduced. It is an indispensable and important tool in modern tunnel engineering. With the continuous advancement of technology, the design and application of TBMs will become more diversified, bringing more possibilities for tunnel construction.