The advance speed of the tunnel boring machine is typically between 10 to 30 meters per day. So, why is the advance speed of such an expensive TBM so slow? Let's analyze the reasons for the slow advance of the TBM.

The advance speed of the tunnel boring machine is influenced by various factors, including geological conditions, machine performance, construction methods, and safety considerations.

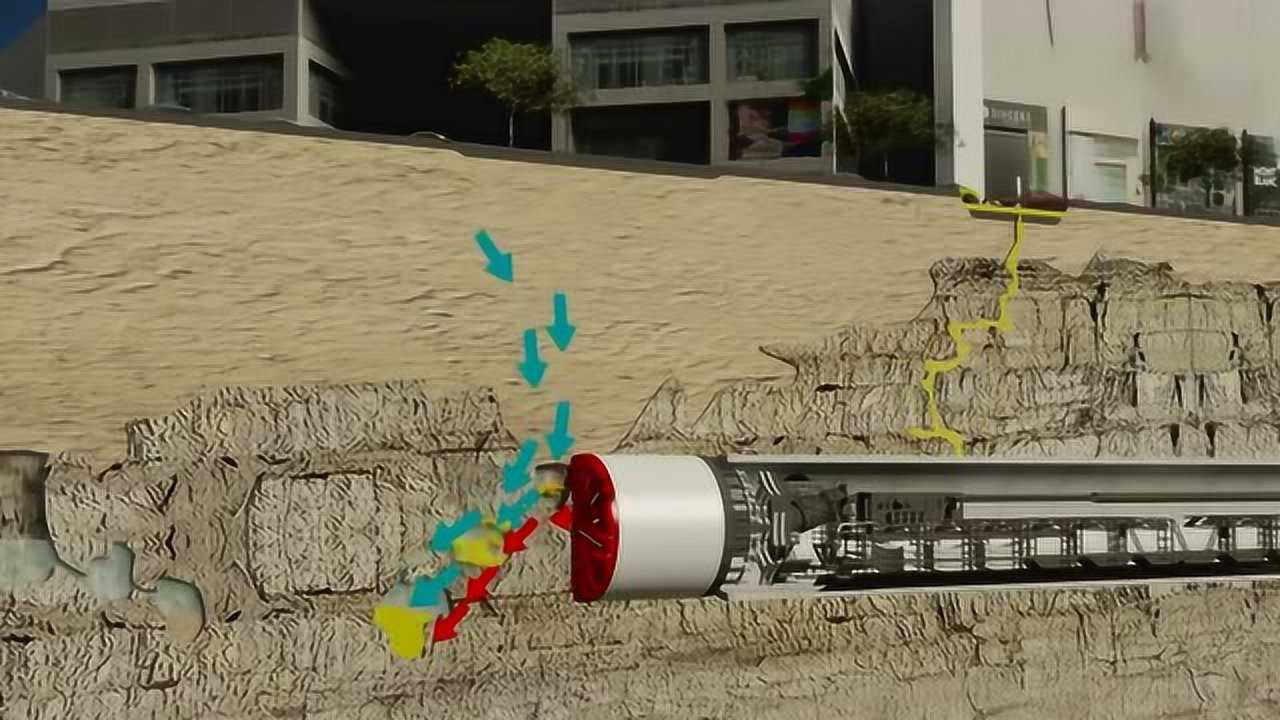

1. Geological conditions: The performance of the TBM varies greatly under different geological conditions. In hard rock, gravel, and other difficult-to-cut formations, the cutter head wears out quickly, necessitating frequent replacement or repair, which significantly reduces the advance speed. In soft soil, silt, and other formations, to prevent ground settlement and tunnel collapse, it may be necessary to reduce the driving speed and increase the pressure of the slurry circulation system. These operations take time, thus affecting the overall construction progress.

2. Machine performance: The performance of the TBM directly affects its excavation capability. If the machine is aging, poorly maintained, or technologically outdated, it may result in low work efficiency. For example, insufficient cutter head rotation speed or torque can limit the advance speed of the TBM.

3. Construction methods: In complex geological environments, construction teams may need to adopt more cautious and meticulous construction methods, such as adjusting cutter head rotation speed or changing propulsion parameters, to ensure construction quality and safety. These adjustments often sacrifice some construction speed.

4. Safety considerations: Safety is the most important consideration in tunnel construction. To avoid accidents, construction teams may choose to reduce the TBM's propulsion speed, especially when traversing sensitive areas or complex geological structures.

5. Technological limitations: Although TBM technology is quite mature, in some special cases, existing technology may not fully solve the encountered problems. For example, in extreme geological conditions such as high water pressure or deep burial, the performance of the TBM may be limited, requiring special technical measures, which may further slow down the advance speed.

6. Environmental protection: In certain environmentally sensitive areas such as city centers or nature reserves, there are strict limitations on the environmental impact of construction. When working in these areas, more environmentally friendly construction methods may be required, which may also reduce the efficiency of the TBM.

7. Logistics support: The normal operation of the TBM requires an adequate supply of materials and logistical support. Insufficient logistics support, such as delayed supply of segments, can also affect the normal propulsion of the TBM.

8. Operator experience: Operators of the TBM need to have high professional skills and rich experience. Novice operators may need time to familiarize themselves with the operation of the machine and respond to various emergencies, and this learning curve may lead to a decrease in construction speed.

9. Equipment failures: During long-term operation, the TBM may experience various failures, such as electrical issues or hydraulic system failures. These failures need to be repaired promptly, otherwise they will seriously affect the efficiency of the TBM.

10. Construction strategy: In some cases, construction teams may intentionally reduce the propulsion speed of the TBM to optimize the quality of the tunnel or adjust the construction schedule to fit the overall project progress.