Composition, Characteristics, Working Principle, and Applications of Hard Rock TBM

Hard Rock TBM (Tunnel Boring Machine) is an advanced mechanical equipment specifically designed for tunnel excavation in hard rock formations. It integrates multidisciplinary engineering technologies such as geology, mechanical engineering, materials science, and automation control to adapt to complex and changing underground environments. Compared to traditional tunneling methods like blasting, TBM technology is more efficient and safer, reducing disturbance to the surrounding environment.

1、How hard rock TBM works

The primary working principle of Hard Rock TBM is to crush and cut rocks using its rotating cutting head at the front. The cutting head is equipped with multiple hard alloy or diamond-inserted tools, which exert enormous impact and shear forces on the rocks under high pressure, breaking them and forming loose rubble piles, which are then removed from the tunnel through conveyors or other conveying mechanisms.

2、Core Components of Hard Rock TBM

Advancing System: Typically composed of multiple hydraulic cylinders, providing the necessary thrust for TBM to overcome rock resistance and advance forward.

Supporting System: As TBM excavates forward, prefabricated concrete or steel support rings are automatically installed at its tail to maintain tunnel stability and prevent collapse.

Navigation System: Utilizes advanced measurement technology to monitor the real-time position and direction of TBM, ensuring accurate excavation along the predetermined trajectory.

Control Room: TBM operators monitor equipment operation status here, manage propulsion, support, navigation systems, and adjust cutting parameters based on geological conditions.

3、Characteristics of Hard Rock TBM

Powerful Cutting Capability: Hard Rock TBM cutting head is designed to handle high-hardness rocks, usually equipped with hard alloy or diamond tools.

Stable Advancing System: Utilizes high-torque main drive and powerful thrust cylinders to ensure stable advancement under hard rock conditions.

Efficient Support Mechanism: Hard Rock TBM is equipped with an automatic support system, such as arch installation machine, which can quickly install prefabricated tunnel lining segments.

Precise Guidance Control: Integrates advanced measurement and guidance systems to ensure accurate excavation along the design path.

4、Applications of Hard Rock TBM

Construction of long tunnels and deep-buried tunnels.

High-speed railway, urban rail transit, and highway tunnel projects.

Development of mines and underground engineering.

Hard Rock TBM is suitable for hard rock geological formations such as granite and limestone. It features a sturdy structure, and its cutting head is typically equipped with high-strength roller cutters and scrapers capable of withstanding high-intensity rock impacts and wear. The advancing system and supporting system of Hard Rock TBM are also specially reinforced to adapt to the challenges of hard rock geology.

China Railway Tunnel Bureau completes early breakthrough of Georgia's Gudauri Tunnel by one month

The Gudauri Tunnel in Georgia, a crucial segment of the north-south corridor KK highway, has achieved breakthrough on April 23rd, 30 days ahead of schedule, thanks to the construction efforts of China Railway Tunnel Bureau. This achievement holds significant technical importance and lays a solid foundation for Georgia's transportation and economic development.

The total length of the north-south corridor KK highway is 22.7 kilometers, with LOT1 project of China Railway Tunnel Bureau Group covering a 10-kilometer stretch, including the 8860-meter Gudauri Tunnel. Designed as a two-lane bidirectional tunnel, it stands as one of the largest infrastructure projects within Georgia. Construction faced complex geological conditions and high technical standards, hence utilizing the world's largest diameter hard rock tunnel boring machine, the "Caucasus" for excavation. Manufactured and designed independently in China, this machine boasts excellent performance parameters, providing strong support for the smooth progress of the project.

The construction of the Gudauri Tunnel posed numerous challenges, with nearly half of its length buried deeper than 700 meters and reaching a maximum depth of 1121 meters. Geological conditions were complex, and the project design and construction adhered to European standards, presenting significant technical difficulties. However, through continuous optimization of construction plans by the China Railway Tunnel Bureau project team and the relentless efforts of construction personnel, remarkable achievements have been made in this tunnel project. Since its inception in September 2021, the "Caucasus" TBM has achieved a monthly maximum excavation rate of 426 meters, setting a new record in the history of large-diameter TBM tunnel construction.

The completion of the north-south corridor KK highway in Georgia holds great significance for the local economy and transportation. This road connects neighboring countries such as Russia, Georgia, Armenia, and Azerbaijan, addressing winter transportation interruptions, reducing travel distances and time, greatly improving traffic efficiency and safety. It benefits not only local residents' travel and freight transportation but also promotes rapid development in cultural tourism, labor employment, and border trade in the northern mountainous regions of Georgia.

Prime Minister Kobakhidze stated that the breakthrough of the Gudauri Tunnel marks a significant milestone for Georgia's largest tunnel, providing a safer passage for local residents and tourists while injecting new impetus into Georgia's economic development. The completion of this project will play an important role in improving Georgia's road network, addressing winter transportation interruptions in the northern mountainous regions, and promoting local economic development.

The breakthrough of the Gudauri Tunnel signifies a significant progress in the north-south corridor KK highway project in Georgia and demonstrates the technical strength and construction level of China Railway Tunnel Bureau in the international infrastructure field. This achievement will further promote cooperation between Georgia and neighboring countries, strengthen its geostrategic and economic status at the Eurasian crossroads, and lay a solid foundation for Georgia's modern transportation system.

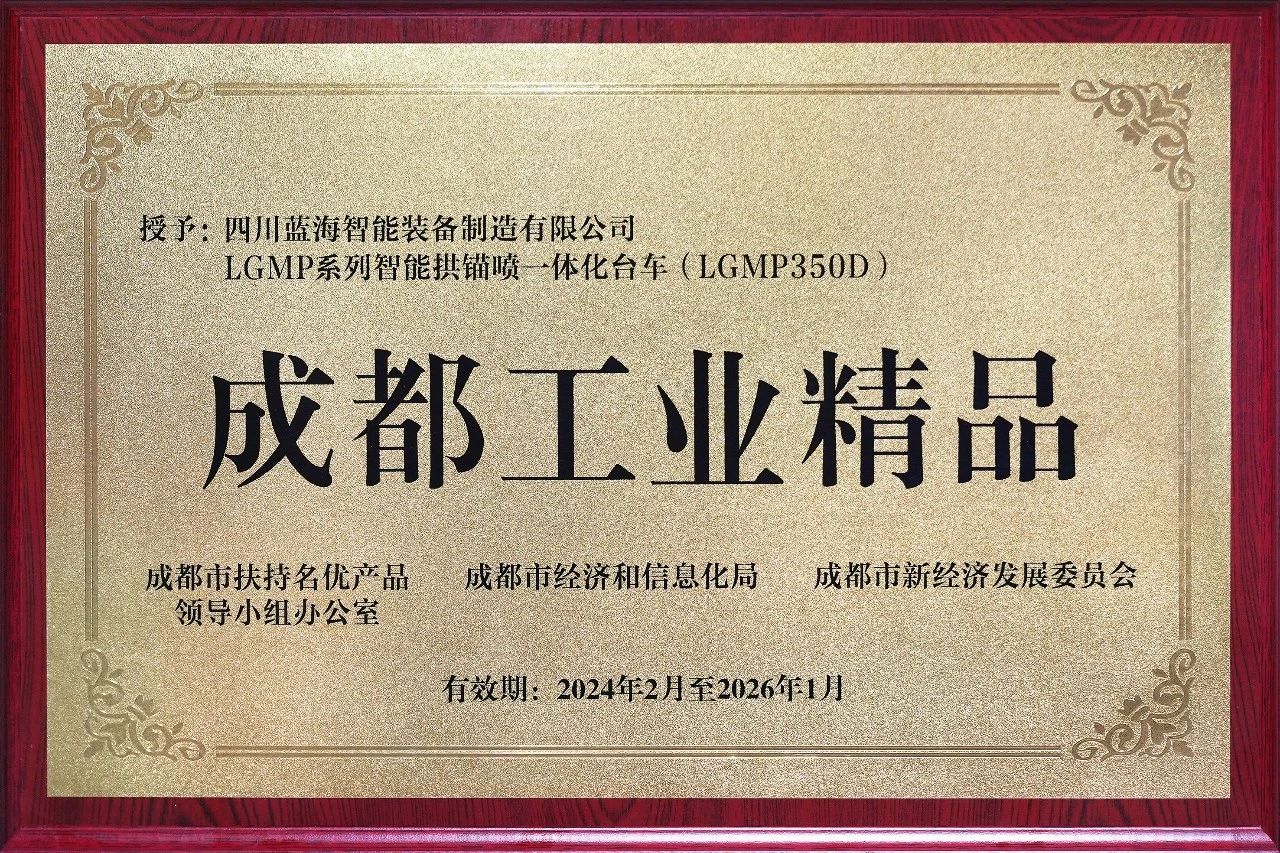

LanHi Intelligent Arch Anchor Spray Platform Cart Honored with

At the end of February 2024, the "Chengdu Made" supply and demand docking event and the Chengdu Industrial Quality Award ceremony were successfully held. This event was guided by the Chengdu Municipal Leading Group for Supporting Famous and Excellent Products and organized by the Chengdu Economic and Information Bureau's New Economy Development Committee (Chengdu Municipal Leading Group for Supporting Famous and Excellent Products Office). At the event, the Blue Ocean Intelligent LGMP350D Integrated Platform Cart for Arch Anchor Spraying, after rigorous selection, was honored with the title of "Chengdu Industrial Quality" and officially launched globally as a new calling card for "Chengdu Manufacturing."

According to the organizers, the establishment of the "Chengdu Industrial Quality" brand and the creation of a high-level platform for supply and demand docking are innovative carriers to implement the manufacturing strong city strategy of the Municipal Party Committee and Government and the decision to implement the "Chengdu Manufacturing Brand." This initiative aims to implement the "Three-Quality" action plan in manufacturing, deepen the expansion of scenario applications, cultivate international influence, and enhance the city (industry) brand and Chengdu's visibility.

The Blue Ocean Intelligent LGMP350D Integrated Platform Cart for Arch Anchor Spraying, which was honored with the "Chengdu Industrial Quality" award, is the first set of products in Sichuan Province. It integrates the functions of wet spraying platform cart, arch frame installation platform cart, and anchor rod platform cart into one, enabling integrated construction of tunnel initial support operations.

The equipment can independently complete the entire process of tunnel initial support, including erection, anchoring, foot locking, advance spraying, etc., with erection taking about 1 hour. The three arms are fully sliding, capable of meeting various types of arch frame installations, various step method operations, and precise adjustment of arch frame positioning. Compared to traditional equipment, it is more convenient in construction, reduces equipment relocation time, has a wider range of applications, and higher mechanization degree, resulting in significant savings in labor, time, and money, as well as improved safety. It can also be equipped with a mobile APP intelligent management platform for efficient management and dual breakthroughs in safety control.

The receipt of the "Chengdu Industrial Quality" honor is not only a recognition of the quality of Blue Ocean products but also an affirmation of Blue Ocean's strategy of adhering to technological innovation to lead development. In the future, we will continue to increase research and development investment, fully enhance the brand value of "Chengdu Industrial Quality," and help "Chengdu Manufacturing" go global. At the same time, we will comprehensively improve our company's product production and delivery capabilities, promote a substantial increase in enterprise output value, create more value for underground engineering digitization construction, and contribute more to accelerating the construction of a manufacturing powerhouse.

How to handle the ore excavated from tunnels? Tunnel ore processing methods

Excavating tunnels often yields a significant amount of soil and ore. If not managed properly, it can harm the ecological environment. So, how is the ore extracted from tunnels processed? Let's discuss the methods for processing tunnel-excavated ore.

The processing methods for ore extracted from tunnels mainly include crushing, screening, ore washing, flotation, magnetic separation, gravity separation, and other physical or chemical beneficiation methods. The specific processing procedures and methods depend on the type, grade, and ultimate use of the ore.

1、Crushing:

Use jaw crushers, cone crushers, hammer crushers, etc., to crush large pieces of ore into smaller ones for subsequent processing.

2、Screening:

Use vibrating screens or trommel screens to grade ores of different particle sizes, separating out the ore particles that meet the requirements.

3、Ore Washing:

Use water flow to wash the ore, removing soil, dust, and other impurities to improve the ore grade.

4、Flotation:

Use flotation machines and flotation reagents to make valuable metal particles adhere to bubbles and float, while other waste sinks to the bottom of the water, thereby recovering valuable metals.

5、Magnetic Separation:

For ores containing magnetic minerals, magnetic separators can be used to separate them.

6、Gravity Separation:

For ores with a higher specific gravity, gravity separation equipment such as jigging machines can be used for separation.

7、Smelting:

For metal ores such as copper, iron, gold, and silver, after beneficiation, they can be sent to smelters for melting to extract pure metals.

8、Comprehensive Utilization:

For complex ores containing multiple valuable metals, a combination of various processing methods can be employed for comprehensive utilization to improve resource recovery rates.

Processing ore excavated from tunnels is a complex process that requires consideration of factors such as ore properties, technical conditions, and environmental impacts to ensure efficient, safe, and environmentally friendly processing.

What is a mobile gantry crane? What are its uses?

A mobile trestle, also known as a mobile lifting platform or a mobile boarding bridge, is an engineering machine primarily used in places such as ports, docks, shipyards, warehouses, etc., to facilitate the rapid and safe transfer of personnel or goods. It typically consists of one or more extendable work platforms, support structures, walking mechanisms, and control systems.

1、The main functions of a mobile trestle include:

Cargo handling: In ports and docks, mobile trestles are used to lift containers directly from ships onto trucks or storage areas ashore, or vice versa, significantly improving loading and unloading efficiency.

Personnel transfer: In ship maintenance and construction, workers can safely transfer from one vessel to another using mobile trestles or reach elevated areas of a ship's hull for operations.

Material handling: mobile trestles can move between different heights and depths, making it easy and efficient to transport goods from ground level to ship decks or from low to high locations.

Space optimization: Due to their mobility, mobile trestles can move within limited spaces as needed, maximizing the utilization of operational areas in ports and docks.

Safe operations: mobile trestles provide a stable work platform, reducing the risks associated with working at heights. They are equipped with necessary safety features such as guardrails and non-slip surfaces to ensure the safety of personnel.

2、The main uses of mobile trestles include:

Construction: In the construction of tall buildings, bridges, and large structures, mobile trestles provide a safe and stable work platform for tasks such as welding, assembly, and cleaning.

Equipment installation and maintenance: In factories, power plants, etc., mobile trestles are used to install and maintain large machinery such as generators and boilers.

Shipbuilding industry: In shipyards, mobile trestles are used for inspecting, repairing, and painting ship hulls, allowing workers to safely perform tasks on the crane's work platform.

Warehousing and logistics: In warehouses and logistics centers, mobile trestles are used for rapid and efficient loading and unloading of goods, particularly in container handling and large cargo transport, saving time and labor.

Rescue and disaster relief: After natural disasters, mobile trestles can serve as temporary bridges or support structures, aiding rescue teams in accessing disaster-stricken areas.