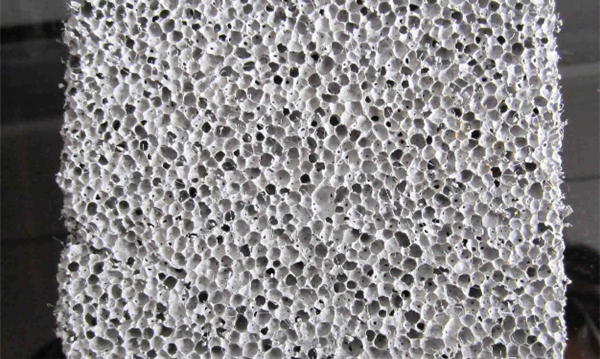

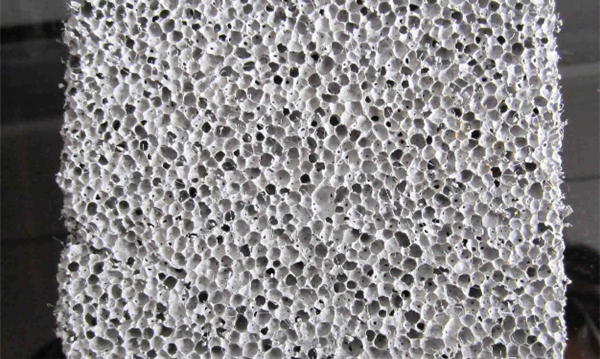

What is the compressive strength of foamed concrete?

What is the compressive strength of foamed concrete?The compressive strength of foamed concrete varies depending on factors such as its density, mix ratio, and curing conditions. Generally, the compressive strength of foamed concrete ranges from 0.5 MPa to 30 MPa.

Lightweight foamed concrete (with lower density) typically has a compressive strength between 0.5 MPa and 3 MPa, while heavyweight foamed concrete (with higher density) can reach compressive strengths of 10 MPa to 20 MPa, or even higher.

It is important to note that the compressive strength of foamed concrete is not its only performance indicator. Its thermal insulation, sound absorption, and sound insulation properties are also very important and should be comprehensively evaluated based on the specific application and requirements.

What Safety Hazards Might Be Encountered During Tunnel Boring Machine (TBM) Construction?

What safety hazards might be encountered during TBM construction? When using a TBM for construction, the following safety hazards may be encountered:

1. Complex geological conditions: Encountering unstable strata, faults, karst caves, etc., can lead to severe consequences such as collapses or water inrushes.

2. Equipment failure: Due to prolonged high-load operation or improper maintenance, the TBM may experience mechanical failures such as cutterhead jamming or hydraulic system leaks.

3. Operational errors: Operators may make mistakes due to fatigue, negligence, or lack of experience, such as mishandling that leads to equipment loss of control.

4. Fire and explosion: Electrical short circuits or oil and gas leaks can trigger fires or explosions, posing threats to personnel and equipment safety.

5. Collapse accidents: Improper support measures or changes in geological conditions can cause local or overall collapses.

6. Toxic and harmful gases: In enclosed or semi-enclosed environments, toxic and harmful gases may be present, posing health hazards to operators.

7. Noise and vibration: Prolonged exposure to high noise and vibration environments can lead to hearing loss and physical discomfort for operators.

8. Limited visibility: Under complex geological conditions, operators’ visibility may be restricted, making it difficult to accurately judge the situation ahead.

9. Improper handling of emergencies: If emergency measures are improperly executed in the face of sudden situations such as mud bursts or equipment failures, the situation may worsen.

10. Poor personnel safety management: Lack of adequate safety training, insufficient protective equipment, or failure to implement strict safety management systems can increase the risk of accidents.

To ensure construction safety, effective preventive measures must be taken, including but not limited to, enhancing geological surveys, improving operators’ professional skills, strictly enforcing safety operating procedures, regularly inspecting and maintaining equipment, and establishing comprehensive emergency response mechanisms. Additionally, on-site supervision and management should be strengthened to ensure all safety measures are effectively implemented.

In which fields are tunnel boring machines widely used?

Compared to traditional manual or mechanical excavation methods, tunnel boring machines (TBMs) have many significant advantages. Firstly, they possess powerful rock-breaking capabilities and high work efficiency, greatly shortening project durations and reducing costs. Secondly, they can adapt to various complex and changing construction environments, easily handling both hard rock and soft soil. Additionally, they offer high safety and reliability, effectively reducing the occurrence of accidents and casualties. So, in which fields are TBMs widely used?

Fields of Application for Tunnel Boring Machines

1、Mining Industry:

TBMs are used to open new mining passages in underground coal and metal mining, improving extraction efficiency.

2、Tunnel Construction:

For the excavation of tunnels for railways, highways, and urban rail transit, TBMs are crucial equipment ensuring the safety and speed of tunnel construction.

3、Water Conservancy Projects:

TBMs are employed in the construction of dams, canals, and irrigation systems, used for excavating channels and building structures.

4、Urban Construction:

In the development of subways, underground malls, parking lots, and other urban infrastructure, TBMs are used to create underground spaces.

5、Geological Exploration:

Specialized drilling TBMs are used to obtain underground information in mineral resource exploration and geological hazard assessment.

6、Defense Engineering:

For the construction of military facilities and underground bunkers, TBMs provide the necessary excavation capabilities.

7、Environmental Engineering:

In environmental projects such as soil remediation and the construction of waste treatment facilities, TBMs are used for land restoration and waste excavation.

8、Energy Development:

Specific types of drilling TBMs are used for well drilling in the exploration and development of oil, natural gas, and other energy resources.

9、Aerospace and Deep-Sea Exploration:

Specially designed TBMs are used in extreme environments for detecting and collecting geological samples.

These fields share the common characteristic of requiring efficient and precise excavation work in complex and harsh environments, and TBMs are the ideal tools designed for such tasks. With technological advancements, the application scope of TBMs continues to expand, providing robust support for human engineering projects and scientific exploration.

How to Monitor and Prevent the Leakage of Toxic and Harmful Gases During Tunnel Boring Machine (TBM) Operations

Monitoring and preventing the leakage of toxic and harmful gases during TBM operations is crucial for ensuring the health and safety of the workers. Below are some effective monitoring and prevention measures:

I. Effective Monitoring of Toxic and Harmful Gas Leaks

1. Use of Gas Detection Equipment: Install fixed or portable gas detectors in the construction area. These devices can monitor the concentration of toxic gases in real-time, such as methane, carbon monoxide, and hydrogen sulfide. Once the gas concentration exceeds the safety threshold, an alarm will be triggered immediately.

2. Optimization of Ventilation Systems: Ensure that the construction area has a good ventilation system. This can be achieved through natural or mechanical ventilation to dilute and remove harmful gases. Special attention should be paid to the ventilation setup in enclosed or semi-enclosed spaces.

3. Environmental Monitoring: Monitor the environment around the construction area to assess the impact of external gas sources, such as nearby industrial emissions or underground reservoirs.

4. Application of Technological Innovations: Explore the use of new monitoring technologies, such as fiber optic sensing technology and wireless sensor networks, to improve monitoring accuracy and coverage.

II. Measures to Prevent Toxic and Harmful Gas Leaks

1. Regular Detection and Maintenance: Conduct regular gas detection at the construction site, especially before entering new work faces. Additionally, regularly calibrate and maintain gas detection equipment to ensure its accuracy and reliability.

2. Safety Training: Provide safety training to workers on the hazards of toxic and harmful gases, so they understand the potential risks and know how to correctly use personal protective equipment (PPE) and handle emergency situations.

3. Use of Personal Protective Equipment (PPE): Provide appropriate PPE, such as respirators and gas masks, and ensure that workers wear them correctly when entering potentially hazardous areas.

4. Adjustment of Work Plans: Adjust work plans based on geological conditions and existing monitoring data to avoid prolonged operations in high-risk areas, or adopt segmented construction and alternating work patterns to reduce risks.

5. Development of Emergency Plans: Develop detailed emergency plans, including evacuation routes, assembly points, and emergency contact information. Conduct regular drills to ensure all personnel are familiar with emergency response procedures.

By implementing these measures comprehensively, it is possible to effectively monitor and prevent the leakage of toxic and harmful gases during TBM operations, thereby ensuring the health and safety of workers.

Excavation Process and Technical Requirements for Pile Head Removal in Geotechnical Engineering

The engineering piles are excavated mechanically to the design elevation. During excavation, care should be taken to avoid the machinery from touching the pile body, and the soil within 200mm around the pile is manually removed. For support piles, due to their dense spacing and proximity to slopes, they are excavated mechanically to a distance of 200mm from the pile, and the remaining portion is manually excavated.

Process:

1、Removal of upper concrete

2、Determination of elevation and cutting of protective piles

3、Opening of gap

4、Removal of reinforcement bars

5、Deepening of gap

6、Drilling of top break

7、Hoisting of broken part

8、Removal of residue

9、Cleaning of pile head

Technical Requirements:

1、Before the removal of the pile head, the surveyor must accurately mark the design elevation of each pile.

2、During construction, the construction team should densely mark around the pile base according to the markings made by the survey team, with at least four markings per pile, marked with conspicuous red paint lines.

3、During the pile head removal operation, in order to protect the effective pile body, a ring cut and subsequent processes should be carried out 10cm above the pile top position, reserving the final 10cm for manual chiseling to ensure the accurate height and elevation of the pile head entering the bearing platform.

4、After lifting the broken pile head out of the pit, the construction team should inspect each pile top to ensure its flatness. If there are any uneven areas, they should be smoothed with a steel chisel.

5、Before the pile head removal operation, consult with technical personnel to confirm the presence of sonic tubes inside the pile base. When removing the pile head, be careful not to damage the sonic tubes. If the sonic tubes extend too far into the pile or are too long, causing difficulty in lifting after the pile is broken, use gas welding to cut the sonic tubes. Immediately after cutting, plug the opening of the sonic tube with cotton cloth to prevent debris from falling into the tube and blocking it, affecting the pile foundation testing.

6、After lifting the pile head with sonic tubes out of the pit, the construction team should inspect each pile top to ensure that the sonic tubes are exposed. If they are not exposed, continue excavating the pile head until the sonic tubes are exposed. If the sonic tubes extending from the pile base are pressed down or deformed during lifting or pile head removal, they should be corrected promptly.

7、When the height of the bearing platform or cap beam is less than the anchorage length of the longitudinal bars, the longitudinal bars at the pile top can be raised to the top of the bearing platform or cap beam and bent into a straight hook to ensure the anchorage length.

The above is the information provided by the construction channel regarding the understanding of the construction process for pile head removal in geotechnical engineering. The construction channel shares more construction knowledge to help you learn construction techniques, discover the beauty of architecture, and explore the path of construction.

Scientific Planning and Strict Management: Detailed Explanation of Tunnel Construction Techniques and Principles

Tunnel engineering, as a crucial part of transportation construction, has a decisive impact on the success of the project. Taking the Qinling Zhongnanshan Highway Tunnel—the longest twin-bore, one-way highway tunnel in the world—as an example, this tunnel spans 18.02 kilometers and fully showcases advanced construction techniques and strict construction principles.

When discussing tunnel construction, the Qinling Zhongnanshan Highway Tunnel, the world's longest twin-bore, one-way highway tunnel, often comes to mind. This tunnel starts in Qingcha, Chang'an District, Xi'an City, and ends in Yingpan Town, Zhashui County, Shangluo City, spanning 18.02 kilometers. With a design speed of 80 kilometers per hour, it takes only 15 minutes to traverse the Qinling Mountains, which form the natural dividing line between northern and southern China. Notably, this world record was entirely designed and constructed by China, incorporating highly human-centric design concepts. This article will detail the construction techniques and principles of tunnel construction.

Principles of Tunnel Construction

Before commencing tunnel construction, a thorough investigation of the weak surrounding rock on-site is essential, with a deep understanding of the design intentions. Based on different geological conditions, practical construction plans are developed. During construction, the following principles must be strictly adhered to:

1. Attention to Geological Conditions:** Accurately understand geological conditions, particularly the characteristics of weak surrounding rock areas.

2. Proactive Control: Maintain proactive control during construction to prevent potential problems.

3. Strict Grouting: Perform grouting reinforcement of the geology to ensure stability.

4. Short Advances: Conduct construction in segments to ensure the quality of each section.

5. Strong Support: Implement effective support measures to ensure the stability of the tunnel structure.

6. Frequent Measurements: Regularly measure and monitor various tunnel parameters to promptly detect and resolve issues.

7. Early Closure: Timely closure of the excavation face to reduce the risk of collapses.

Tunnel Construction Techniques

The techniques used in tunnel construction vary depending on the classification of the surrounding rock:

- Full-face Method: Suitable for Class III rock sections, involving one-time full-face excavation to ensure construction efficiency.

- Step Method Excavation: Suitable for Class IV and V rock sections, involving step-by-step excavation and gradual support to ensure safety.

For support, initial support measures include rock bolts, steel meshes, and shotcrete, with advanced construction of the invert to ensure tunnel stability. The arch walls are constructed in a single pass to ensure structural integrity and durability.

In sections with active fault zones or requiring seismic fortification, full-circle steel arch frames and double-layer φ42 small guide pipes for the arch are used for advanced support to enhance seismic performance. Lining inside the tunnel employs lining trolleys to ensure construction precision and efficiency.

Technological Applications in Construction

During construction, advanced geological prediction and forecasting are crucial. Techniques such as deep blast hole detection and infrared detection confirm the geological conditions ahead and detect differences between design and actual geology. In critical geological hazard sections, advanced horizontal drilling techniques ensure accurate geological understanding. Meticulous measurements are conducted throughout the construction process, analyzing settlement observation data to adjust construction plans in a timely manner.

Tunnel construction is a complex and precise engineering task requiring scientific planning and strict management. By adhering to scientific construction principles and adopting advanced construction techniques, the smooth progress of tunnel construction and the long-term safe operation of tunnels can be ensured. The successful construction of the Qinling Zhongnanshan Highway Tunnel is a powerful testament to this approach.

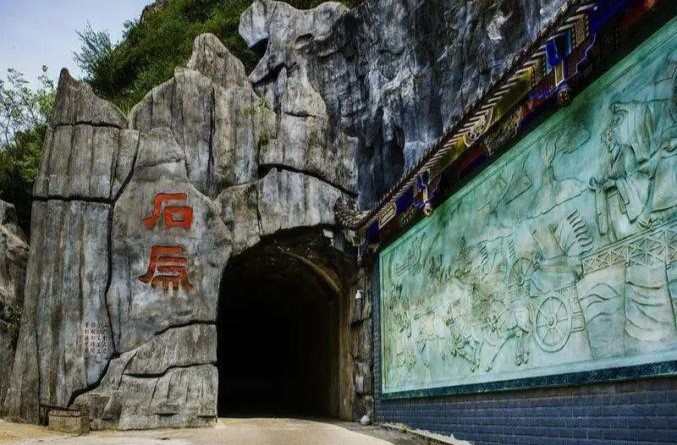

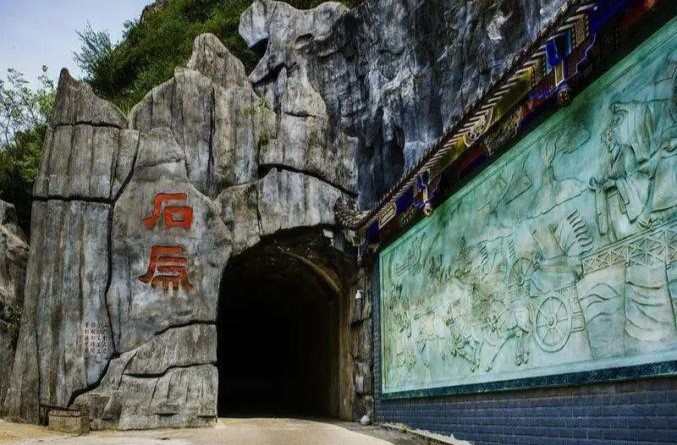

Shimen Tunnel: An Engineering Marvel Across Time

In the towering mountains of southwestern China lies an engineering marvel that quietly narrates a tale of human wisdom and courage—Shimen Tunnel. This tunnel is not only a monumental achievement in China's transportation history but also a shining gem in the world of tunnel construction. Behind this tunnel lies a legendary story that spans millennia, about how ancient craftsmen used their ingenuity and bravery to carve a passage through the daunting natural environment.

In the fourth year of Yongping during the Eastern Han Dynasty (61 AD), Emperor Ming of Han, Liu Zhuang, ordered the construction of the Baoxie plank road to strengthen control and development of the western regions. This road was not only a crucial link between Guanzhong and Hanzhong but also a strategic point vital for maintaining national unity and stability. However, the construction faced unprecedented difficulties. The road was blocked by mountain rocks, presenting a significant challenge to the craftsmen.

According to the "Compilation of Baogu Valley Relics," when faced with these obstacles, the craftsmen employed a primitive but ingenious method called the "fire-setting and water-quenching" technique. They would first pile up large amounts of firewood and ignite it to heat the rocks until they were extremely hot. Then, they would rapidly cool the rocks with cold water, exploiting the thermal expansion and contraction properties of the rocks to weaken them, making excavation easier. This method, though primitive, demonstrated remarkable creativity and courage, showcasing the ancient craftsmen's wisdom and determination.

However, this method has not been without controversy. Some later scholars questioned its effectiveness, arguing that it was difficult to control the damaged areas and that the rock surfaces might not be smooth enough. Despite these doubts, the successful excavation of Shimen Tunnel remains a significant milestone in China's tunnel history. It not only solved the transportation bottleneck but also provided invaluable experience and lessons for future tunnel construction.

After years of arduous efforts, the Shimen Tunnel was finally completed in 62 AD. The tunnel is 16 meters long, 3.45-3.75 meters high, and 4.1-4.4 meters wide, allowing modern small cars to pass through with ease. It became the most crucial section of the "Difficult Road to Shu" and a key point controlling the Hanzhong Plain and Sichuan. The idiom "Repairing the plank road openly while secretly crossing the Chencang" refers to the Baoxie Road. This idiom not only reflects the clever use of ancient military strategies but also highlights the Shimen Tunnel's strategic importance in military history.

The successful excavation of the Shimen Tunnel is a testament to the intelligence and bravery of ancient craftsmen and marks a significant breakthrough in China's tunnel construction history. It provided valuable experience and insights for future projects and left us with a precious cultural heritage. Let us remember this history, inherit that spirit, and continue to write new chapters in China's transportation development.

Today, the Shimen Tunnel has become a stunning attraction, drawing countless visitors to experience its historical grandeur and significance. The spirit of self-reliance and hard work embodied in its construction continues to inspire us to move forward and create a better future.

China's Seven World-Class Tunnel Engineering Marvels

China has repeatedly created miracles in the field of tunnel engineering. These world-class projects not only lead in technology but also showcase China's ambition in infrastructure development. Here are seven ultra-world-class tunnel projects.

1、The World's Longest Twin-Tube Highway Tunnel - Qinling Zhongnanshan Tunnel

Located in Shaanxi Province, the Qinling Zhongnanshan Tunnel, with a total length of 36.04 kilometers, is currently the world's longest twin-tube highway tunnel. The tunnel starts in Wutai Township, Chang'an District, Xi'an City in the north and ends in Yingpan Town, Zhashui County, Shangluo City in the south. During its construction, the engineering team overcame various challenges such as faults, water inflow, and rock bursts. It officially opened to traffic on January 20, 2007, boosting Shaanxi's highway mileage to the top in Western China.

2、The World's Largest Diameter Shield Tunnel - Shanghai Yangtze River Tunnel

The Shanghai Yangtze River Tunnel, with a total length of 8.9 kilometers, has an inner diameter of 13.70 meters and an outer diameter of 15.43 meters, making it the world's largest diameter shield tunnel. The tunnel's upper level is a three-lane highway in one direction, while the lower level is reserved for rail transit space. This project connects Pudong and Changxing Island, forming the 25.5-kilometer Yangtze River Tunnel and Bridge project together with the Yangtze River Bridge.

3、The World's Highest Altitude Long Highway Tunnel - Sichuan-Tibet Highway Queershan Tunnel

The Queershan Tunnel on the Sichuan-Tibet Highway is situated at an altitude of 4,378 meters and has a total length of 8.955 kilometers, making it the world's highest altitude long highway tunnel. Since its commencement in 2012, the construction team has overcome harsh environmental conditions such as high altitude, severe cold, and oxygen deficiency, creating a miracle in high-altitude construction.

4、The World's Longest Plateau Railway Tunnel - New Guanjiao Tunnel on the Qinghai-Tibet Railway

Located on the Qinghai-Tibet Plateau, the New Guanjiao Tunnel on the Qinghai-Tibet Railway spans altitudes between 3,324.05 and 3,494.45 meters, making it the longest plateau railway tunnel in the world. Since its commencement in 2007, the engineering team has tackled challenges like extreme cold, oxygen deficiency, and complex geological conditions, ensuring the smooth progress of the project.

5、The World's Highest Altitude Plateau Railway Tunnel - Qilian Mountain Tunnel

In May 2014, the Qilian Mountain Tunnel on the Lanzhou-Xinjiang High-Speed Railway was fully connected. With a total length of 16.336 kilometers and a maximum altitude of 3,607.4 meters, it is currently the world's highest altitude, highest construction standard, and most challenging high-speed railway tunnel, earning the title of "The Highest High-Speed Railway Tunnel in the World."

6、The World's Largest Cross-Section Highway Tunnel - Gongbei Tunnel of the Hong Kong-Zhuhai-Macao Bridge

The Gongbei Tunnel, with a total length of 2,741 meters and an excavation cross-section of 336.8 square meters for the 255-meter dark excavation section, is the world's largest cross-section highway tunnel. During its construction, the "curved pipe shed + freezing method" was adopted, breaking multiple world records, and forming an integral part of the Hong Kong-Zhuhai-Macao Bridge Zhuhai Link.

7、The World's Longest Immersed Tube Tunnel - Immersed Tube Tunnel of the Hong Kong-Zhuhai-Macao Bridge

The immersed tube tunnel of the Hong Kong-Zhuhai-Macao Bridge, with a total length of 6.7 kilometers, consists of 33 immersed tubes and one closure section. It is the world's longest and deepest immersed tube tunnel, with a maximum installation depth exceeding 40 meters. This project, known as the Everest of transport engineering, poses extremely high technical challenges.

These tunnel projects not only achieve technical breakthroughs but also demonstrate the wisdom and courage of Chinese engineers during their construction. These world-class projects witness China's outstanding achievements in the field of infrastructure construction.

China's 8 Super Bridge Projects: Each a World-Class Engineering Feat

Bridges are not only pathways connecting two places but also marvels of engineering that showcase the continual breakthroughs of human wisdom. In China, these bridges are not only multifunctional but also achieve world-leading standards in design and construction. Below, we introduce several representative bridges that have set records in length, span, height, and more, leaving a significant mark on the history of world bridges.

1. Hong Kong-Zhuhai-Macao Bridge: The Longest Sea-Crossing Bridge in the World

In December 2009, construction began on the Hong Kong-Zhuhai-Macao Bridge, connecting the Hong Kong Special Administrative Region, Zhuhai City in Guangdong Province, and the Macao Special Administrative Region. This bridge is the first mega sea-crossing transportation project co-constructed by Guangdong, Hong Kong, and Macao under the "one country, two systems" framework. After six years of preparation and nine years of construction, the 55-kilometer-long bridge was officially opened to traffic at the end of 2018. This mega project combines bridges, tunnels, and artificial islands, and its construction difficulty earned it the title "Mount Everest of Bridges." It was also named one of the "New Seven Wonders of the World." During its construction, scientists and engineers created over 400 new patents and broke seven world records.

2. Beipanjiang Bridge: The Highest Bridge in the World

The Beipanjiang Bridge is located at the border between Guizhou and Yunnan provinces, connecting Liupanshui City in Guizhou and Xuanwei City in Yunnan. It is part of the Hangrui Expressway. Although it is only 1,341 meters long, the bridge deck is 565 meters above the valley floor, equivalent to the height of a 200-story building and close to the main body height of Shanghai Tower, making it the highest bridge in the world. In May 2018, the Beipanjiang Bridge won the Gustav Lindenthal Medal at the 35th International Bridge Conference. The main bridge piers are 269 meters and 247 meters high, and its 720-meter main span ranks second in the world among similar bridges.

3. Dashengguan Yangtze River Bridge: The World's First Six-Track Railway Bridge

Nanjing Dashengguan Yangtze River Bridge is China's first high-speed railway bridge over the Yangtze River. As a crucial and landmark project of the Beijing-Shanghai High-Speed Railway, it is also the cross-river passage for the Shanghai-Hanrong Grade I Railway Trunk Line and Nanjing Metro. Construction began on July 18, 2006, with a total investment of 4.56 billion yuan. The bridge is 9.273 kilometers long, and its main bridge is the world's first six-track railway bridge, carrying double lines for the Beijing-Shanghai High-Speed Railway, double lines for the Shanghai-Hanrong Railway, and double lines for the Nanjing Metro, with a design speed of 300 kilometers per hour. It holds four world records for being the largest, longest, heaviest, and fastest high-speed railway bridge.

4. Wufengshan Yangtze River Bridge: The World's First High-Speed Railway Suspension Bridge

The Wufengshan Yangtze River Bridge is located in Taizhou, Jiangsu Province, connecting the Lianyungang-Huai'an-Yangzhou-Zhenjiang Railway and the southern extension of the Beijing-Shanghai Expressway. It is the third road-rail bridge over the Yangtze River in Jiangsu Province. The bridge is 6.409 kilometers long, with a main bridge length of 1.432 kilometers and a combined road-rail section length of 1,444.799 meters. The bridge surpasses Japan's Seto Ohashi Bridge's Minami Bisan-Seto Bridge to become the world's first road-rail suspension bridge in terms of load and design speed.

5. Hutong Yangtze River Bridge: The Largest Span Road-Rail Cable-Stayed Bridge

The Hutong Yangtze River Bridge is 11,072 meters long, with a main span of 1,092 meters, making it the world's first road-rail cable-stayed bridge with a span exceeding one kilometer. The bridge integrates national railway, intercity railway, and expressway functions, with the upper layer carrying a six-lane expressway and the lower layer accommodating four railway lines. As a joint cross-river passage for the Hutong Railway, Tong-Suzhou-Jia Intercity Railway, and Xitong Expressway, the Hutong Yangtze River Bridge sets new world records in structure and functionality.

6. Danyang-Kunshan Grand Bridge: The Longest Railway Bridge in the World

Located on the Beijing-Shanghai High-Speed Railway, the Danyang-Kunshan Grand Bridge is approximately 164.8 kilometers long, making it the longest railway bridge in the world. Its construction significantly enhances the efficiency of the Beijing-Shanghai High-Speed Railway and demonstrates China's robust capabilities in railway bridge construction.

7. Wuhan Yangtze River Bridge

The Wuhan Yangtze River Bridge is 1,670.4 meters long and is the first road-rail bridge built over the Yangtze River after the founding of the People's Republic of China, holding significant historical importance. It is not only a feat of engineering but also a symbol of national construction achievements.

8. Jiangyin Yangtze River Bridge

The Jiangyin Yangtze River Bridge is 3,071 meters long and is the fourth longest suspension bridge in the world. This bridge serves as an important transportation route over the Yangtze River and its elegant design has become a landmark along the river.

These bridges showcase China's brilliant achievements in bridge construction, with each representing the world's advanced engineering technology of its time. They are not only crucial nodes in the transportation network but also tourist attractions and landmarks, displaying the excellence of Chinese bridge construction.

What famous tunnel engineering cases do you know? The world's top ten tunnel engineering cases

Do you know any famous tunnel engineering projects? Here are the top ten tunnel engineering projects in the world:

1. Gotthard Tunnel:

Location: In the Swiss Alps, crossing the Gotthard Pass.

Features: With a total length of 57.09 km, it is the world's longest railway tunnel, designed with twin tubes providing two separate tunnel passages.

Construction Challenges: It traverses hard rock geology, requiring solutions for high pressure and high temperature environments, using TBM (Tunnel Boring Machine) technology.

Significance: Improves north-south traffic in Europe, reduces travel time, and significantly boosts regional economic development.

2. Channel Tunnel:

Location: Connects the UK and France, crossing the English Channel.

Features: With a length of 50.45 km, it is the world's longest underwater tunnel, designed for rail, linking high-speed train services between the two countries.

Construction Challenges: Faced high-pressure water, complex geological structures, and extreme weather conditions, utilizing advanced shield technology and tunnel lining systems.

Significance: Enhances transportation and economic exchange between the UK and France, reducing cross-border travel time.

3. Seikan Tunnel:

Location: Between Honshu and Hokkaido in Japan, crossing the Tsugaru Strait.

Features: With a total length of 53.85 km, it is the world's longest rail and road tunnel, with an underwater section of 23.3 km.

Construction Challenges: Dealt with complex geological conditions, including seabed sediments and volcanic activity areas, using a combination of shield and drilling-blasting methods.

Significance: Strengthens the connection between Honshu and Hokkaido, significantly impacting local economy and transportation.

4. Turin-Milan High Speed Rail Tunnel:

Location: Italy, connecting the cities of Turin and Milan.

Features: Approximately 35.5 km long, it is Italy's longest high-speed rail tunnel, utilizing advanced tunnel lining and ventilation systems.

Construction Challenges: Crosses the pre-Alps, requiring solutions for safety issues in highland tunnel construction.

Significance: Significantly reduces travel time between Turin and Milan, enhancing transportation efficiency in northern Italy.

5. Laerdal Tunnel:

Location: Norway, connecting Oslo and Bergen.

Features: At 24.51 km, it is the world's longest road tunnel, featuring complex ventilation systems and emergency shelters.

Construction Challenges: Crosses hard rock layers, needing solutions for large-scale drainage and ventilation issues, employing TBM technology.

Significance: Improves traffic safety and convenience in western Norway, positively impacting local tourism and economic development.

6. Gotthard Road Tunnel:

Location: Switzerland, part of the Alpine highway.

Features: Approximately 17.1 km long, it is the world's longest road tunnel, designed with twin tubes providing two separate tunnel passages.

7. Eastern Suburbs Railway Tunnel:

Location: Sydney, Australia, part of the city's metro system.

Features: At 15.5 km, it is Australia's longest rail tunnel, using shield technology to traverse Sydney's complex urban geology.

Construction Challenges: Required construction in a busy city center while avoiding impacts on surrounding buildings and infrastructure.

Significance: Relieves traffic pressure in Sydney's urban area, improving public transportation efficiency and contributing to long-term urban development.

8. Dali-Ruili Railway Tunnel:

Location: Yunnan Province, China, a key control project of the Dali-Ruili Railway.

Features: Approximately 14.5 km long, it is the longest railway tunnel in southwest China, crossing the Hengduan Mountains.

Construction Challenges: Faced high altitudes, complex geology, and harsh climate conditions, using a combination of TBM and drilling-blasting methods.

Significance: Essential for completing the railway network in southwest China, promoting local economic development.

9. Qingma Bridge and Tunnel:

Location: Hong Kong, connecting Kowloon Peninsula and the New Territories.

Features: Approximately 13.4 km long, including both the Qingma Bridge and tunnel parts, serving as a major traffic artery in Hong Kong.

Construction Challenges: Required solutions for deep-water construction and complex geological conditions, employing advanced bridge and tunnel construction technologies.

Significance: Greatly improves transportation in Hong Kong, promoting regional economic development.

10. Dazhushan Tunnel:

Location: Dali, Yunnan, connecting Dali and Ruili.

Features: Approximately 14.5 km long.

Construction Challenges: Encountered various risks such as complex fault zones, water and mud inrush, weak surrounding rock deformation, high geothermal heat, and rock bursts. The geological conditions are extremely complex and variable, with water inrush filling a West Lake every three months. Only 156 meters were excavated in 26 months; construction began in 2008 and is still ongoing.

Significance: Once completed, the Dali-Ruili Railway will revive the ancient Southern Silk Road, highlighting Yunnan's role as a bridge to Southeast and South Asia, significantly promoting the economic and social development of the regions along the route.