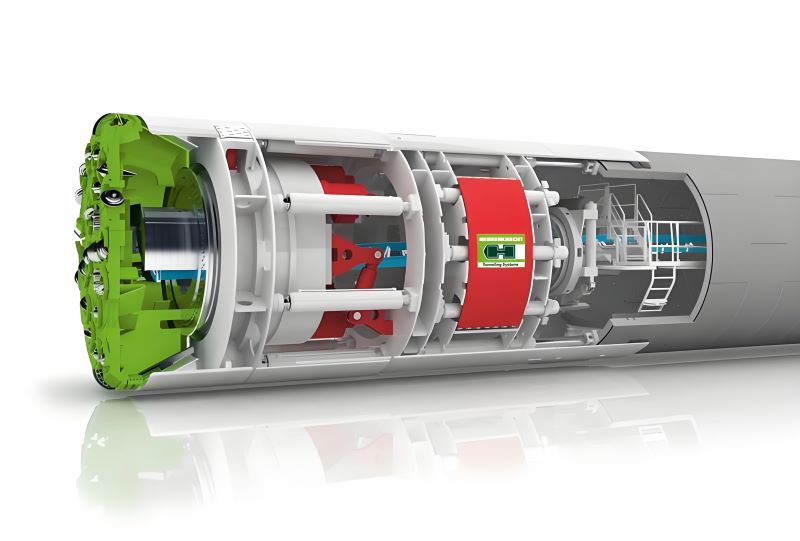

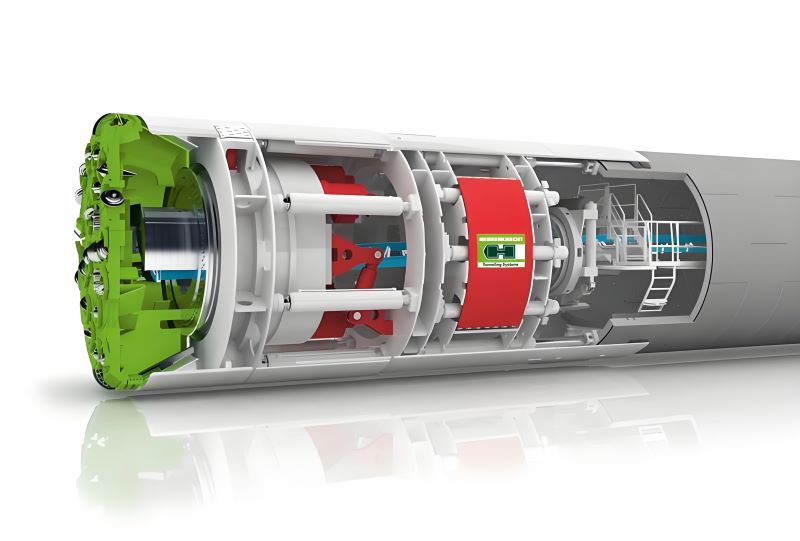

Normal pressure tunnel boring machine, which can operate while keeping the working face pressure the same as the atmospheric pressure on the ground

Normal pressure tunnel boring machine is a kind of tunnel boring equipment, which is used in underground tunnels, mines and other projects. It usually includes a shield body and a main drive arranged in the shield body. It can operate while keeping the working face pressure the same as the atmospheric pressure on the ground. The characteristic of this tunnel boring machine is that its design allows operators to work in a normal atmospheric pressure environment, thus avoiding the impact of high pressure environment on human health.

Take a normal pressure cutterhead tunnel boring machine as an example. Its main drive includes a drive box, the middle part of which is a central channel that runs through the front and back, and also includes a drive device fixed relative to the drive box, which is used to provide power for the rotation of the corresponding cutterhead. The rear end of the drive box that encloses the central channel is sealed with a sealing plate, which blocks the rear end of the central channel to enclose the central cabin, and the central part of the sealing plate is provided with a central swivel joint installation hole for installing the central swivel joint.

Such a structure enables the center cabin to be integrated on the main drive. Compared with the method of nesting the center cabin shell protruding backward in the main drive and using its inner cavity to form the center cabin, the structure of integrating the center cabin with the main drive can further miniaturize the radial size of the main drive while ensuring the radial size of the center cabin, thereby miniaturizing the radial size of the tunnel boring machine.

In addition, a single gate for normal pressure tool change is also used in the normal pressure tool change technology of the tunnel boring machine. For example, a single gate for normal pressure tool change of the tunnel boring machine includes a front cover and a rear cover that are fixedly connected, and a cavity is formed between the two. A sealing component is arranged at the edge of the cavity, and a knife plate is arranged in the cavity. A driving device (such as a cylinder) that can drive the knife plate to reciprocate inside and outside the cavity is arranged on the connecting side of the front cover and the rear cover, thereby realizing the opening and closing of the gate. This gate is not only compact in structure, but also convenient and safe to operate.

Normal pressure tunnel boring machines are suitable for tunnel excavation under various geological conditions, especially in urban subways, railway tunnels, water conservancy projects and other fields. Because it can operate under normal pressure, it greatly improves the work efficiency and safety of workers, and also reduces the impact on workers' health. With the continuous advancement and innovation of technology, the performance and automation level of normal pressure tunnel boring machines are constantly improving, making it an indispensable and important equipment in modern underground engineering.

Different types of normal pressure tunnel boring machines may have some differences in structure and function, and the specific characteristics and advantages will vary depending on the design and application scenarios. If you want to know more about the details of normal pressure tunnel boring machines, you can consult our professional engineering and technical personnel.

What are the components of a vehicle-mounted wet spraying machine? What are the main components of a vehicle-mounted wet spraying machine?

A vehicle-mounted wet spraying machine is a mobile mechanical device that integrates the functions of concrete mixing, conveying and spraying. Its main components include:

1. Mixing system

- Mixing barrel: used to mix cement, sand, gravel, water and other additives to ensure the uniformity of concrete.

- Mixing blades: rotate in the mixing barrel to fully mix the raw materials.

- Drive device: usually an electric motor or a hydraulic motor, providing power for the rotation of the mixing blades.

2. Pumping system

- Concrete pump: transports the mixed concrete to the spraying location through a pipeline. Common pump types include plunger pumps and double piston pumps.

- Delivery pipeline: connects the pump and the spray gun to withstand the delivery of high-pressure concrete.

3. Spraying system

- Spray gun (nozzle): used to accurately spray concrete onto the construction surface, usually equipped with adjustable spray angle and distance.

- Spray control device: controls the operation of the spray gun, including switches, pressure regulation, etc.

4. Power system

- Engine: Provides the power required for the operation of the equipment, which can be a diesel engine or a gasoline engine.

- Transmission system: Transfers the power of the engine to the mixing system and the pumping system.

5. Operating system

- Control panel: The operator monitors and adjusts the entire spraying process through the control panel, including parameters such as pumping speed and spraying pressure.

- Remote control device: Some models of vehicle-mounted wet spraying machines are equipped with remote controls, making the operation more flexible and convenient.

6. Auxiliary system

- Compressed air system: Provides compressed air required for spraying, usually including air compressors and air tanks.

- Water system: Used to clean the equipment and adjust the fluidity of concrete, including water tanks and water pumps.

7. Chassis and suspension system

- Chassis: The basic structure that carries the entire equipment, usually with a certain off-road capability to adapt to different construction sites.

- Suspension system: Ensures the stability and comfort of the vehicle when driving on uneven ground.

8. Electrical system

- Generator: Powers the electrical equipment of the vehicle-mounted wet spraying machine, including lighting, control systems, etc.

- Battery: starts the engine and powers the vehicle's electronic devices.

9. Safety System

- Emergency stop button: quickly stops the equipment in an emergency.

- Alarm device: sounds an alarm when the equipment is abnormal to alert the operator.

These main components work together to ensure that the vehicle-mounted wet spraying machine can complete concrete spraying operations efficiently and safely. During use, regular inspection and maintenance of these components are very important to ensure the reliability and durability of the equipment.

A new era in tunnel construction: The rise of wet concrete spray trucks

With the continuous development of tunnel construction technology, the requirements for tunnel project quality, operational safety and occupational health are also constantly increasing. Against this background, mechanized equipment is gradually used in various processes of tunnel construction to replace traditional manual labor. Among them, the concrete wet spray trolley has become the mainstream equipment for shotcrete support operations.

The concrete wet spray trolley has demonstrated its unique advantages in the initial support operations of long tunnels, which has greatly promoted the application of mechanized construction in tunnel projects. Compared with traditional artificial sprayed concrete, wet spraying trolleys have the following significant advantages:

1. Improve construction efficiency: The concrete wet spray trolley can operate continuously, which greatly shortens the construction time and improves the construction efficiency. Compared with manual spraying, mechanized equipment can more accurately control the spray volume and coverage, thereby reducing material waste.

2. Ensure project quality: The wet spray trolley can spray concrete evenly and stably, ensuring the uniformity and stability of the supporting structure and significantly improving the project quality. Mechanized construction reduces the impact of human factors on project quality and ensures high standards of support operations.

3. Improve work safety: During tunnel construction, safety issues have always been a top priority. The use of concrete wet spray trolleys can reduce workers' working time in harsh environments and reduce safety risks. At the same time, the use of mechanized equipment can avoid human operating errors and further ensure construction safety.

4. Improve occupational health: Traditional manual spraying concrete operations often produce a large amount of dust and noise, which adversely affects the health of workers. The concrete wet spray trolley adopts closed operation, which effectively reduces dust and noise pollution, improves the working environment of workers, and enhances occupational health.

The application of concrete wet spray trolleys in tunnel construction not only improves construction efficiency and project quality, but also significantly improves operational safety and occupational health. With the advancement of science and technology and the continuous development of construction technology, the concrete wet spray trolley, as an ideal choice for tunnel engineering support, will play an increasingly important role in future tunnel construction, pushing tunnel construction into a more mechanized , a new era of intelligence.

In what fields can vehicle-mounted wet spraying machines be used? Scope of application of vehicle-mounted wet spraying machines

The vehicle-mounted wet spraying machine is an efficient and flexible concrete construction equipment. It integrates concrete mixing, conveying and spraying functions on a vehicle, and is suitable for various complex terrains and difficult working environments. This equipment plays an important role in concrete construction in tunnels, mines, water conservancy projects, slope protection and other fields. Let's take a look at the scope of application of vehicle-mounted wet spraying machines.

The scope of application of vehicle-mounted wet spraying machines is relatively wide, mainly including the following aspects:

1. Tunnel engineering: Whether it is a railway tunnel, a highway tunnel or a hydraulic tunnel, the vehicle-mounted wet spraying machine can provide efficient concrete spraying support for the inner wall of the tunnel.

2. Underground engineering: such as underground parking lots, underground shopping malls, underground warehouses, etc., used to reinforce and support structures.

3. Slope protection: Concrete spraying is carried out on the slopes along roads, railways, etc. to enhance the stability of the slopes and prevent landslides and collapses.

4. Foundation pit support: In the foundation pit project of building construction, concrete is sprayed on the foundation pit wall to protect the construction safety.

5. Water conservancy projects: such as the reinforcement and repair of dams and channels.

6. Mine tunnels: used for the support and reinforcement of mine tunnels to ensure the safety of mine operations.

The vehicle-mounted wet spraying machine has a wide range of applications, including tunnel projects (railway, highway, hydraulic tunnel), underground projects (parking lots, shopping malls, warehouses, etc.), slope protection (roads, slopes along railways), foundation pit support (construction foundation pit), water conservancy projects (dam, channel reinforcement and repair) and mine tunnels (support and reinforcement), etc., and can play an important role in all kinds of projects that require concrete spraying support.

The reasons and prospects for the rapid development of concrete wet spraying trolleys in China in recent years

In recent years, concrete wet spray trolleys have developed rapidly in China and have gradually become an important equipment in shotcrete construction. Compared with traditional dry spray machines, wet spray trolleys have obvious technical advantages and market demand driving forces, making them more and more widely used.

Technical advantages promote the development of wet spray trolleys

1. Health and environmental advantages:

Wet spray technology significantly reduces the dust concentration during the construction process and reduces the hazards to workers' health. This is especially important in today's construction environment where worker health and environmental protection are of paramount importance.

2. Efficient construction:

The production efficiency of the concrete wet spraying trolley is much higher than that of the dry spraying machine, which can reach 10 to 30 cubic meters per hour. This efficient production capability greatly increases construction speed and overall project progress.

3. Low rebound rate:

The rebound rate of wet spraying technology is less than 10%. Compared with the traditional dry spraying process, it greatly reduces material waste and improves construction quality and economic benefits.

4. High-quality construction:

The water-cement ratio is easy to control during wet spraying, which greatly improves the uniformity and overall quality of the concrete and ensures the consistency of the construction effect.

Environmental protection policies and promotion of mechanized construction

The country's requirements for environmental protection are becoming increasingly strict, and mechanized construction has become a general trend. It is clearly stated in various design documents and construction specifications that the wet spraying process needs to be used. This is not only the result of policy guidance, but also an inevitable choice to improve construction quality and efficiency.

3. Rising labor costs and advantages of mechanization

As labor costs rise year by year, the advantages of mechanized operations become more and more obvious. The concrete wet spray trolley can not only more than double the construction efficiency, but also reduce the reliance on highly skilled workers and further reduce construction costs.

4. Domestic manufacturers’ R&D and market maturity improvements

Domestic concrete wet spray trolley manufacturers continue to improve their research and development capabilities, and their products have gradually matured and achieved standardization and serialization. These advances have significantly increased the market's acceptance and recognition of wet spray trolleys.

5. Perfect after-sales service system

The comprehensive after-sales service provided by the concrete wet spraying trolley manufacturer provides strong technical support for the operation, use and maintenance of the equipment. This not only ensures the normal operation of the equipment, but also further promotes the widespread application of wet spray trolleys.

Wide application and broad prospects

Concrete wet spray trolleys are widely used in shotcrete support operations in railway tunnels, highway tunnels, water conservancy culverts, mine tunnels, dam slopes, construction foundation pits and military engineering. As people's awareness of environmental protection increases and the quality requirements for sprayed concrete increase, the market demand for concrete wet spraying trolleys will further expand.

Taken together, the concrete wet spraying trolley has developed rapidly due to its advantages such as health and environmental protection, efficient construction, low rebound rate, and high-quality construction, driven by national policies and market demand. In the future, with the further advancement of technology and the continuous expansion of the market, the development prospects of concrete wet spraying trolleys will be even broader.

Tunnel boring machines can be divided into three types according to the number of shields

Shield boring machines, also known as boring machines, are key equipment in modern tunnel engineering and are widely used in tunnel construction projects such as subways, highways, railways, water diversion, and sewage drainage. According to the number of shield shells, shield boring machines can be divided into single-shield boring machines, double-shield boring machines and triple-shield boring machines. Each type of shield machine plays a different role in the construction process and is suitable for different geological conditions and construction needs.

1. Single shield boring machine

The single-shield tunnel boring machine is the most basic type of shield tunneling machine and is suitable for areas with relatively stable geological conditions. Its main feature is that it has only one shield, which is used to support the tunnel wall during excavation and prevent tunnel collapse. The single-shield boring machine has a simple structure, easy operation, and relatively low cost. It is often used in short-distance or shallow-depth tunnel projects.

2. Double-shield boring machine

The double-shield boring machine adds a shield to the single shield to enhance the safety and stability of tunnel construction. The double-shield tunnel boring machine is suitable for areas with complex geological conditions, especially in unstable geology such as soft soil and sand. It has significant advantages. The double shield design can provide stronger support during the excavation process, effectively reduce the risk of deformation and collapse of the tunnel wall, and improve construction efficiency and safety.

3. Three-shield boring machine

The three-shield boring machine is a high-end equipment among shield boring machines and has the strongest support capacity and adaptability. Three-shield boring machines are usually used in tunnel projects with extremely complex geological conditions and extremely difficult construction, such as deep tunnels, high-pressure water layers, etc. Its triple shield design not only provides stronger support, but also better handles geological changes and external pressure during the excavation process, ensuring the continuity and safety of construction.

With the continuous development of shield machine technology, the types and functions of shield machine are also constantly improved and enriched. Single-shield, double-shield and triple-shield tunnel boring machines have their own characteristics and are suitable for different geological conditions and construction needs. In practical applications, engineers will select the appropriate shield machine type based on specific project requirements and geological conditions to ensure the smooth progress of tunnel construction and improvement of project quality. The wide application of shield machines not only improves the efficiency and safety of tunnel construction, but also promotes the progress and development of underground engineering technology.

In what fields can vehicle-mounted wet spraying machines be used? Scope of application of vehicle-mounted wet spraying machines

The vehicle-mounted wet spraying machine is an efficient and flexible concrete construction equipment. It integrates concrete mixing, conveying and spraying functions on a vehicle, and is suitable for various complex terrains and difficult working environments. This equipment plays an important role in concrete construction in tunnels, mines, water conservancy projects, slope protection and other fields. Let's take a look at the scope of application of vehicle-mounted wet spraying machines.

The scope of application of vehicle-mounted wet spraying machines is relatively wide, mainly including the following aspects:

1. Tunnel engineering: Whether it is a railway tunnel, a highway tunnel or a hydraulic tunnel, the vehicle-mounted wet spraying machine can provide efficient concrete spraying support for the inner wall of the tunnel.

2. Underground engineering: such as underground parking lots, underground shopping malls, underground warehouses, etc., used to reinforce and support structures.

3. Slope protection: Concrete spraying is carried out on the slopes along roads, railways, etc. to enhance the stability of the slopes and prevent landslides and collapses.

4. Foundation pit support: In the foundation pit project of building construction, concrete is sprayed on the foundation pit wall to protect the construction safety.

5. Water conservancy projects: such as the reinforcement and repair of dams and channels.

6. Mine tunnels: used for the support and reinforcement of mine tunnels to ensure the safety of mine operations.

The vehicle-mounted wet spraying machine has a wide range of applications, including tunnel projects (railway, highway, hydraulic tunnel), underground projects (parking lots, shopping malls, warehouses, etc.), slope protection (roads, slopes along railways), foundation pit support (construction foundation pit), water conservancy projects (dam, channel reinforcement and repair) and mine tunnels (support and reinforcement), etc., and can play an important role in all kinds of projects that require concrete spraying support.

Which one is better, wet spray machine or wet spray manipulator? The difference between wet concrete spraying machine and wet spraying manipulator

Wet spray concrete machines and wet spray manipulators are two different types of equipment used for spraying concrete in the construction industry. They differ significantly in structure, function and application. Here's a detailed comparison of the two devices.

Difference 1. Different equipment types

- Concrete wet spraying machine: This is a traditional concrete spraying equipment, usually consisting of a mixing device and a spraying device. It is suitable for small-scale spraying operations and is relatively simple to operate.

- Wet spray manipulator: This is a more advanced and automated equipment that usually includes a robotic arm and a spray head. It enables more complex injection paths and higher injection accuracy.

Difference 2. Different sizes of equipment

- Wet concrete spraying machine: relatively simple, usually small in size and with certain limitations in operational flexibility.

- Wet spray manipulator: It is a large-scale intelligent equipment with a higher degree of automation.

Difference 3. Degree of automation

- Wet concrete spraying machine: usually requires manual operation. Although a certain degree of automation can be achieved, it mainly relies on the operator's experience and technology.

- Wet spray manipulator: It has a high degree of automation capability and can spray concrete more flexibly and accurately, covering a larger area. Automatic injection can be realized through programming, which reduces the influence of human factors and improves construction quality and efficiency.

Difference 4. Scope of application

- Concrete wet spraying machine: suitable for small projects and simple spraying tasks, such as lining of small tunnels, slope reinforcement, etc.

- Wet spray manipulator: suitable for large-scale, complex-shaped spray operations, such as full-section spraying of large tunnels, concrete pouring of special structures, etc.

Difference 5. Construction efficiency

- Wet concrete spraying machine: Due to its operating limitations, the construction efficiency is relatively low.

- Wet spray manipulator: Due to its high degree of automation and flexibility, the construction efficiency is much higher than that of traditional wet spray machines.

Difference 6. Cost-effectiveness

- Wet concrete spraying machine: The initial investment is low, but due to limitations in construction efficiency and quality, it may not have a cost advantage in the long run.

- Wet spray manipulator: Although the initial investment is high, due to its high efficiency and high precision, it can save a lot of manpower and time costs in the long run.

Difference 7. Operation difficulty

- Concrete wet spraying machine: The operation is relatively simple, but the technical requirements for the operator are high.

- Wet spray manipulator: It requires certain technical training to operate skillfully, but once mastered, the operation is not difficult.

Concrete wet spraying machines and wet spraying robots each have their own advantages and applicable scenarios. When choosing which equipment to use, the decision should be based on specific project needs, budget and construction conditions. With the technological advancement of the construction industry, wet spray manipulators are gradually becoming the mainstream shotcrete equipment due to their high efficiency and high precision.

Application and advantages of LANHI's wet concrete spraying trolley in various engineering construction projects

As an indispensable and important equipment in modern engineering construction, wet concrete spraying trolleys are widely used in mine tunnels, railway and highway tunnels, water conservancy culverts, various underground projects, high-rise building foundation pits, and military projects. Its application in spraying and anchor support operations has greatly improved construction efficiency and safety.

Application fields of LANHI's wet concrete spraying trolleys

1. Mine tunnels: In mining operations, wet concrete spraying trolleys can quickly and effectively support mine tunnels, ensure the safety of operators, and prevent accidents such as landslides.

2. Railway and highway tunnels: Railway and highway tunnel construction requires an efficient support system. The application of wet spraying trolleys not only improves the construction speed, but also ensures the structural stability of the tunnel.

3. Water conservancy culverts: In water conservancy projects, wet spraying trolleys can quickly spray concrete to enhance the waterproof performance and structural strength of culverts.

4. Various underground projects: Whether it is subway construction or underground pipe gallery construction, concrete wet spraying trolleys play an important role in ensuring the quality of the project and the safety of construction workers.

5. High-rise building foundation pit: In the construction of high-rise buildings, foundation pit support is a key link. The wet spraying trolley can spray concrete quickly and evenly to improve the stability of the foundation pit.

6. Military engineering: In the construction of military facilities, the wet spraying trolley is also an indispensable equipment. It can quickly build protective fortifications and improve the concealment and anti-strike capabilities of the project.

Advantages compared to traditional dry spraying machines

Concrete wet spraying trolleys have significant advantages over traditional dry spraying machines. The most prominent feature is that wet spraying operations can significantly reduce dust concentration. Traditional dry spraying machines will generate a lot of dust during operation, which not only affects the construction environment, but also poses a serious threat to the health of construction workers. Wet spraying technology effectively reduces the generation of dust by adding water, improves the construction environment, and protects the health of workers.

In addition, the spraying effect of the wet spraying trolley is more uniform, the concrete adhesion is better, and a tighter support layer can be formed, which improves the overall strength and durability of the support structure.

The importance of LANHI's concrete wet spraying trolley in modern engineering construction cannot be ignored. It not only improves construction efficiency and quality, but also significantly improves the construction environment and protects the health of workers. With the continuous advancement of technology, wet spraying trolleys will play a greater role in more fields and provide more reliable protection for various engineering construction.

When tunnel excavation encounters a fault zone, how to control the step length when using the step method?

The step length needs to be determined based on factors such as the stability of the surrounding rock, the cross-sectional dimensions of the tunnel, the operating space of the construction machinery, and the requirements of the support structure. The following are some general principles and methods for controlling the step length:

1. Surrounding rock stability: A longer step length can be used for more stable surrounding rock, while a shorter step length is required for unstable surrounding rock to reduce disturbance to the surrounding rock and ensure construction safety.

2. Tunnel cross-sectional dimensions: When the cross-sectional dimensions are larger, the step length can be appropriately increased, but the operating space of the construction machinery and the difficulty of support should also be considered.

3. Construction machinery operating space: The step length should meet the operating requirements of the construction machinery, such as the operating space of excavators, loaders, etc., in order to improve construction efficiency.

4. Support structure requirements: Determine the appropriate step length based on the type and design requirements of the support structure. For example, when anchor support is used, the step length should be adapted to the length of the anchor.

5. Experience and field tests: Adjust the step length based on the experience of similar projects and the results of field tests. During the construction process, the rationality of the step length can be verified by monitoring the deformation of the surrounding rock and the stress of the support structure, and necessary adjustments can be made.

Generally speaking, the step length is between 1D (D is the tunnel span) and 2D, but the specific length needs to be comprehensively considered and optimized according to the actual situation. At the same time, during the construction process, operations should be strictly carried out in accordance with the construction plan, and support and monitoring should be strengthened to ensure the safety and quality of tunnel excavation. If special circumstances are encountered, such as changes in surrounding rock conditions, groundwater outburst, etc., the step length and construction method should be adjusted in time.