Tunnel anchor drill, an underground engineering equipment used for installing anchor rods in tunnels to provide support

Tunnel anchor drilling rig is a kind of equipment specially used in tunnel and underground engineering, which is used to install anchors to provide support. Here are some main contents about tunnel anchor drilling rig:

1. Purpose

Tunnel anchor drilling rig is mainly used for initial support and reinforcement of tunnel. By drilling holes in the tunnel wall and installing anchors, the stability of the tunnel structure can be improved, and landslides and rock displacement can be prevented.

2. Working principle

Tunnel anchor drilling rig drives the drill tool through a hydraulic or electric system to drill holes in the tunnel surrounding rock. After the drilling is completed, the anchor is inserted into the hole and fixed in the rock layer by grouting or mechanical locking, thereby playing a supporting role.

3. Classification

Tunnel anchor drilling rigs can be divided into the following categories according to the power source and usage scenario:

- Hydraulic anchor drilling rig: driven by a hydraulic system, suitable for most tunnels and underground projects.

- Electric anchor drilling rig: driven by electricity, suitable for engineering scenarios with sufficient power supply.

- Handheld anchor drill: suitable for working in narrow spaces, easy to operate, but relatively small in power.

4. Features

- Efficient construction: can quickly and accurately drill holes on the tunnel wall and install anchors, improving construction efficiency.

- Adapt to different geology: can work in rocks and soils of various hardnesses, adapting to different tunnel geological conditions.

- Precision drilling: ensure the accuracy and verticality of the drilling, and ensure the installation quality of the anchor.

- Flexible operation: many tunnel anchor drills have flexible operating arms that can cope with different angles and position requirements.

5. Application scenarios

- Initial tunnel support: reinforce the tunnel wall by installing anchors to improve the stability of the tunnel.

- Tunnel reinforcement and repair: when problems occur in existing tunnels, anchor reinforcement operations are carried out.

Tunnel anchor drills are widely used in the construction of railway and highway tunnels, especially in rock tunnels, playing a key support role. It is also used in the reinforcement construction of underground spaces such as mine tunnels, underground parking lots and subway projects.

Advantages and disadvantages of open excavation method and construction steps

Open Cut Method is a common method for tunnel or underground structure construction, mainly used for the construction of shallow buried tunnels and underground buildings. This method excavates the ground first, completes the construction of the tunnel or underground structure, and then backfills and restores the surface. The following are some key steps and characteristics of the open cut method:

I、Advantages and Disadvantages of Open Cut Method

1. Advantages:

1> Simple construction: The open cut method is relatively simple to operate and is suitable for shallow buried tunnels and underground structures.

2> Low cost: Compared with other tunnel construction methods (such as shield method or mining method), the construction cost of the open cut method is usually lower.

3> Fast construction progress: Since the surface is completely exposed, the transportation and installation of construction equipment and materials are more convenient, and the construction speed is faster.

2. Disadvantages:

1> Large impact on the environment: Surface excavation will have a greater impact on the surrounding environment, especially in densely populated urban areas, which may cause traffic disruptions, noise and dust pollution.

2> Limited scope of application: The open-cut method is only applicable to shallow buried projects, not deep buried tunnels and underground structures.

3> Risk of surface subsidence: If the construction process is not properly controlled, it may cause surface subsidence and affect the safety of surrounding buildings.

II、Construction steps of the open-cut method

1. Surface excavation: First, fence the construction area and dig up the surface soil until the design elevation is reached. Slope stability needs to be considered during excavation, and support structures (such as retaining walls or soil nail walls) may be used to prevent collapse.

2. Support structure construction: After excavating to the designed depth, temporary or permanent support structures are installed according to geological conditions and construction requirements to ensure the stability of the excavated space.

3. Structural construction: Construction of tunnels or underground buildings in the excavated space, usually including the casting or installation of the bottom plate, side walls and top plate.

4. Waterproofing and drainage: In order to prevent groundwater from infiltrating, waterproofing measures will be taken during the construction process, such as laying a waterproof layer or drainage system to ensure the dryness and stability of the structure.

5. Backfilling and surface restoration: After the structure is completed, backfilling operations are carried out, the earthwork is compacted layer by layer, and finally the surface is restored to its original or designed state, such as restoring roads, green spaces or other surface facilities.

Open-cut method is widely used in shallow buried projects such as subway stations, underground passages, and underground pipe galleries. With the advancement of urbanization, open-cut method plays an important role in the development of urban underground space.

What are the construction methods for integral lining? Types and precautions of construction methods for integral lining

What are the construction methods for integral lining? The construction methods of integral lining are mainly divided into the following categories, each with its applicable scenarios and characteristics, as well as the construction precautions for integral lining.

I、Construction method of integral lining

1. Sliding mode construction method

The sliding formwork construction method is a relatively advanced method in the construction of integral lining. It uses a continuously rising sliding formwork to pour and form in one go, and has the advantages of fast construction speed, good integrity, and smooth surface. Suitable for long-distance and large section tunnel lining construction.

2. Trolley construction method

The trolley construction method uses movable trolleys as templates and is suitable for medium length tunnel construction. During construction, the trolley is in place, the formwork is fixed, and then concrete pouring is carried out. After the concrete reaches a certain strength, move the trolley to the next position and repeat the construction process. This method is flexible in construction and has strong adaptability.

3. Segmented construction method

For projects with complex geological conditions and significant changes in tunnel cross-sections, the segmented construction method can be adopted. According to the different geological conditions and tunnel sections, the lining is designed and constructed in sections, and the construction of the next section is carried out after each section is completed. This method has high flexibility, but relatively low construction efficiency.

4. Assembled integral lining

Prefabricated integral lining is a type of prefabricated component assembly, which involves prefabricating concrete lining sections in the factory and then assembling them inside the tunnel. This method has a fast construction speed, but requires high precision for prefabricated components and requires significant transportation and lifting space.

5. Spray concrete lining

Although shotcrete lining itself is not a typical construction method for integral lining, in some special conditions such as rapid construction or unstable geological conditions, shotcrete can be used as initial support first, and integral lining can be constructed when conditions permit.

II、 Construction precautions

1. When selecting construction methods, factors such as geological conditions, cross-sectional size, construction conditions, and schedule requirements of the tunnel should be fully considered.

2. Adequate preparation should be made before construction, including geological survey, design optimization, construction organization design, etc., to ensure construction quality and safety.

3. During the construction process, the quality of concrete should be strictly controlled to ensure the strength and durability of the lining.

4. Pay attention to construction safety, especially when working in environments with complex geological conditions and abundant groundwater, effective safety measures should be taken.

The construction method selection of integral lining should comprehensively consider multiple factors to achieve the best engineering effect and economic benefits.

The structural characteristics, construction technology, and application scenarios of integral lining

Integrated lining is an important form of support in tunnel construction. Its main function is to provide a sturdy and stable inner wall for the tunnel to resist external soil pressure, groundwater pressure, and possible seismic forces. At the same time, it can also improve the environmental conditions inside the tunnel, such as reducing water seepage and improving ventilation efficiency.

Structure and Characteristics

Integral lining is usually made of reinforced concrete or prestressed concrete, which has good integrity and durability. Its structural characteristics are as follows:

1. Integrity: The integral lining is continuously poured or assembled to form a seamless whole, which can effectively disperse loads and improve the safety and stability of the structure.

2. High stiffness: Compared to other forms of lining, integral lining has higher stiffness, which can better resist external loads and reduce deformation.

3. Good waterproof performance: By setting a waterproof layer inside the lining, the integral lining can effectively prevent groundwater infiltration and protect the internal structure of the tunnel from erosion.

4. Strong durability: Using high-quality concrete materials and construction techniques, the integral lining has a longer service life and reduces the frequency of maintenance and repair.

Construction technology

The construction of integral lining usually includes the following steps:

1. Excavation and initial support: Firstly, the tunnel outline is formed through excavation, and then initial support is carried out to ensure construction safety.

2. Waterproof layer construction: Before lining, lay a waterproof layer to prevent groundwater infiltration.

3. Template installation: Install templates according to design requirements to ensure the shape and size of the lining.

4. Concrete pouring: Use a concrete pump or pouring equipment to evenly pour concrete into the formwork to form a lining.

5. Maintenance and formwork removal: After the concrete is poured, maintenance is carried out, and the formwork is removed after reaching a certain strength.

Application scenarios

Integrated lining is widely used in subway tunnels, highway tunnels, water conservancy tunnels, mining tunnels and other engineering projects, especially in situations with complex geological conditions, abundant groundwater or high requirements for tunnel stability. The advantages of integrated lining are more obvious.

What is prefabricated arch installation? Steps and precautions for installing prefabricated arches

What is prefabricated arch installation? Prefabricated arch installation is a commonly used construction technique in modern bridge, tunnel, and large building construction. It combines the high efficiency of prefabricated components with the flexibility of on-site installation, which can significantly improve construction speed and quality, while reducing construction costs and environmental impact. The following are the basic steps and precautions for installing prefabricated arches:

Basic steps

1. Design and prefabrication: In factories or prefabrication sites, high-precision mechanical equipment and molds are used to prefabricate arch components according to engineering design drawings. During the prefabrication process, it is necessary to strictly control the size and material quality to ensure the accuracy and stability of on-site installation.

2. Transportation and preparation: Prefabricated arch components are transported to the construction site by specialized transportation vehicles. Before installation, the site needs to be leveled and reinforced to ensure that the ground is stable and able to withstand the weight of the arch and construction loads.

3. Positioning and installation: Use a crane or other lifting equipment to lift the arch components to the predetermined position, and ensure that the levelness and verticality of the arch meet the design requirements through precise measurement and adjustment. During the installation process, temporary support structures may be required to ensure the stability of the arch frame before it is fully secured.

4. Connection and fixation: The connection between the arch components and between the arch and the ground is usually achieved through welding, bolt connection, or prestressed reinforcement. Quality inspection is required at the connection to ensure connection strength and sealing.

5. Acceptance and maintenance: After installation, strict quality inspection and acceptance are required to ensure the stability and safety of the arch structure. During use, regular maintenance checks should be conducted to promptly identify and address any potential damage or looseness, thereby extending the service life of the arch frame.

Precautions

·Safety first: During the construction process, it is necessary to strictly follow safety operating procedures, use qualified protective equipment, and ensure the safety of construction personnel.

·Environmental impact: The installation of prefabricated arches should minimize the impact on the surrounding environment, including noise control, waste disposal, and ecological protection.

·Quality control: Strict quality control is required at every stage from design to installation to ensure the structural safety and durability of prefabricated arches.

The continuous development and innovation of prefabricated arch installation technology provide more efficient, environmentally friendly, and safe construction solutions for the modern construction industry, and are an important force in promoting the industrialization of construction and the development of green buildings.

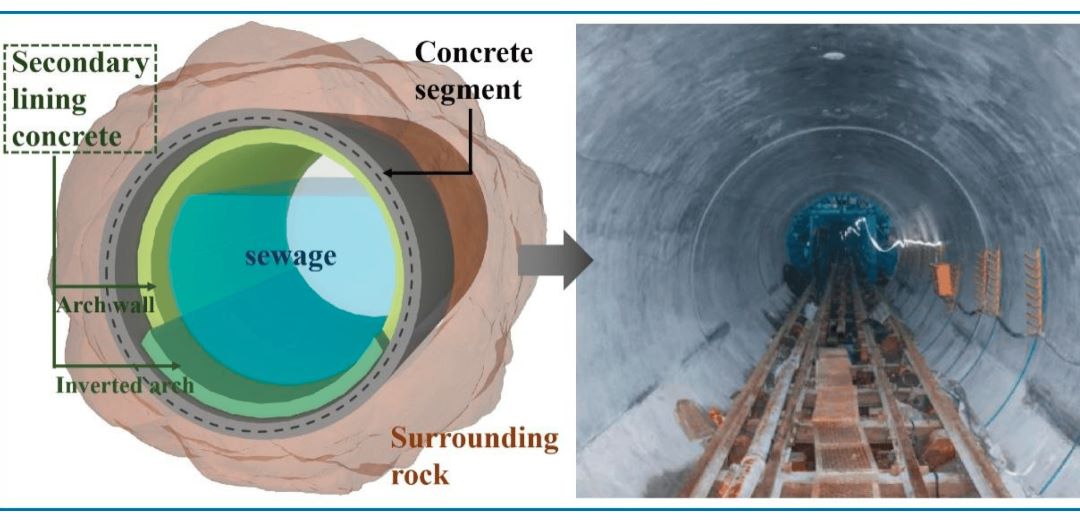

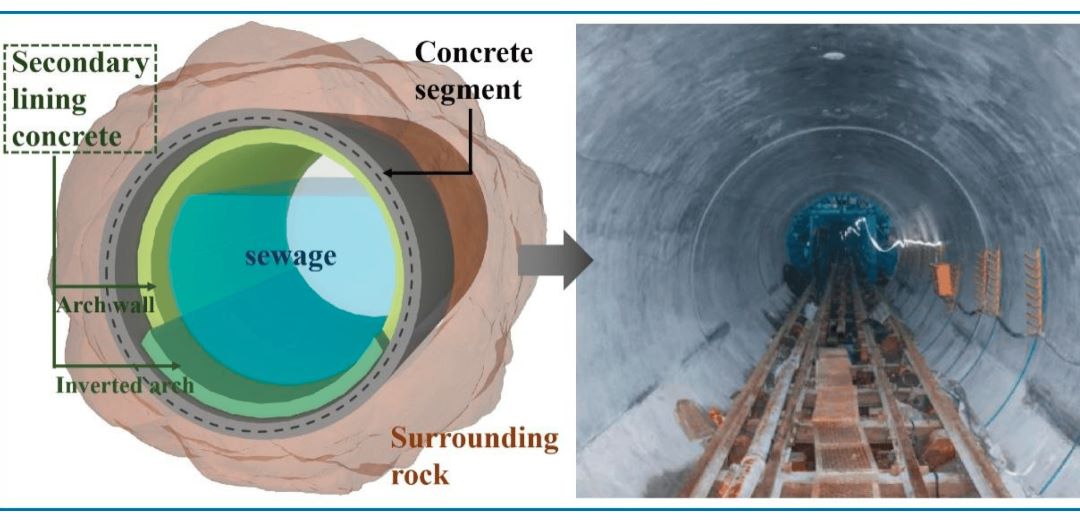

What is the role of secondary lining in composite lining?

Secondary lining plays a crucial role in composite lining systems and is an important component of tunnel structures. It is mainly used to enhance the overall stability of tunnels and provide long-term support and protection. Composite lining usually includes initial support (such as shotcrete, anchor rods, and steel arches) and secondary lining, and the combination of the two can more effectively cope with various geological conditions and stress changes encountered during tunnel excavation and later operation.

Secondary lining plays the following important roles in composite lining:

I、 Bearing function

1. Provide long-term stable support

-The initial support mainly bears the immediate pressure of the surrounding rock after excavation during the construction process, but over time, the deformation of the surrounding rock may continue to develop. As a structure constructed in the later stage, the secondary lining can provide long-term stable support for the tunnel and jointly bear the surrounding rock pressure with the initial support.

-For example, in soft rock tunnels, the creep characteristics of the surrounding rock are obvious, and secondary lining can effectively control the long-term deformation of the surrounding rock, ensuring the safety and stability of the tunnel structure.

2. Take on some of the water pressure

-When there is groundwater in the tunnel, the secondary lining can bear some of the water pressure, especially in the case of local defects in the waterproof layer. The secondary lining can play a certain role in waterproofing and anti-seepage, preventing groundwater from damaging the tunnel structure.

-In areas like Shenzhen with abundant groundwater, the anti water pressure effect of secondary lining is particularly important.

II、 The role of safety reserve

1. Improve the safety factor of the tunnel

-As a safety reserve, secondary lining can play a timely role in preventing serious accidents such as tunnel structure collapse when local damage or insufficient bearing capacity occurs in the initial support.

-For example, when a tunnel encounters unexpected disasters such as earthquakes or explosions, secondary lining can provide additional protection for personnel and equipment inside the tunnel.

2. Ensure construction safety

-During tunnel construction, the application of secondary lining can provide a relatively safe working environment for construction personnel. Especially in areas with complex geological conditions and poor rock stability, timely construction of secondary lining can reduce construction risks and ensure smooth progress of construction.

3、 Waterproof function

III. Form a waterproof barrier

-The secondary lining is usually poured with concrete with good impermeability performance, and a waterproof layer is set between it and the initial support to jointly form the waterproof system of the tunnel. The secondary lining can effectively prevent groundwater from seeping into the interior of the tunnel, ensuring the normal functioning of the tunnel.

-Taking tunnels in the Shenzhen area as an example, due to their proximity to the ocean and high groundwater levels, the waterproof effect of the secondary lining is crucial for the durability of the tunnel.

2. Prevent leakage from damaging the structure

-The leakage of groundwater not only affects the functionality of tunnels, but also causes corrosion and damage to tunnel structures. The good waterproof performance of the secondary lining can avoid the erosion of groundwater on the initial support and internal facilities of the tunnel, and extend the service life of the tunnel.

IV、 Aesthetic and decorative effects

1. Improve the internal environment of the tunnel

-The surface of the secondary lining can be leveled and decorated to make the interior of the tunnel more beautiful and tidy, improving the comfort and safety of driving.

-For example, fireproof and anti-corrosion coatings can be applied to the surface of the secondary lining, and lighting facilities and signage can be installed to provide good visual effects and directional information for tunnel users.

2. Enhance the overall image of the tunnel

-For some important traffic tunnels or urban underground passages, the appearance quality of the secondary lining directly affects the overall image of the tunnel. Through careful design and construction, the secondary lining can become a beautiful scenery line in the city.

The role of secondary lining in composite lining systems is multifaceted. It not only enhances the safety and stability of tunnel structures, but also provides various functions such as waterproofing, fireproofing, and anti-corrosion. It is an important component to ensure the long-term safe operation of tunnels.

Advantages of hydraulic wet spraying trolleys in underground engineering and modern tunnel construction

In the field of modern tunnel construction and underground engineering, hydraulic wet spraying trolleys, as an innovative technology, are gradually replacing traditional dry spraying processes, bringing significant benefits and environmental advantages to the industry. Its core advantage is to significantly reduce the dust concentration in the working environment, reduce the rebound rate, and improve the quality of sprayed concrete, thereby providing strong protection for the health of construction workers and engineering efficiency.

1. Dust control, protect the health of workers

In the traditional dry spraying process, high concentrations of dust not only seriously deteriorate the working environment, but also pose a potential threat to the respiratory system of construction workers. In contrast, the hydraulic wet spraying trolley greatly reduces the dust generation during the spraying process by pre-mixing concrete with water, effectively improving the working environment and ensuring the health and safety of workers.

2. Reduce rebound rate and improve material utilization

In the dry spraying process, the high rebound of concrete often leads to serious material waste. The hydraulic wet spraying trolley can significantly reduce the rebound rate of concrete by accurately controlling the water-cement ratio. According to measured data, the rebound rate can be reduced from 15%-50% to below 10%, which greatly improves the utilization rate of materials and reduces costs.

3. Improve concrete quality and ensure project quality

The advantages of wet spraying technology are also reflected in the improvement of concrete quality. By accurately controlling the water-cement ratio, the hydraulic wet spraying trolley ensures the uniformity and stability of concrete, avoids the poor hardening phenomenon caused by uneven moisture, thereby greatly improving the quality of sprayed concrete and providing a solid guarantee for the durability and safety of the project.

The wide application of hydraulic wet spraying trolleys marks a technological innovation in the field of tunnel construction and underground engineering. It not only effectively improves the working environment and ensures the health of construction workers, but also makes important contributions to the economic benefits and sustainable development of engineering projects by improving material utilization and concrete quality.

How to reduce rebound and dust when spraying concrete?

How to reduce rebound and dust when spraying concrete? When spraying concrete, the following measures can be taken to reduce rebound and dust:

Measures to reduce rebound:

1. Optimize the mix ratio: Use a reasonable mix ratio of cement, aggregate, water and admixtures to improve the cohesion and sprayability of concrete.

2. Control the spray distance and angle: The distance between the nozzle and the sprayed surface should be 0.6-1.2 meters, and the spray angle should be as perpendicular to the sprayed surface as possible.

3. Appropriate wind pressure and water pressure: According to the performance of the sprayer and the transportation distance of the concrete, adjust the appropriate wind pressure and water pressure. Generally, the wind pressure is controlled between 0.1-0.15MPa.

4. Layered spraying: The layer thickness should not be too large, generally 5-10 cm. Layered spraying can make the concrete adhere better to the sprayed surface.

5. Strengthen operator training: Improve the technical level and experience of operators so that they can master the spraying skills.

Measures to reduce dust:

1. Strengthen ventilation: Set up good ventilation equipment in the spraying operation area to discharge dust in time.

2. Wet spraying process: The wet spraying concrete process can significantly reduce the generation of dust.

3. Control the spraying speed: Avoid too fast spraying speed to reduce the dust generated by the friction between concrete and air.

4. Install water rings on the nozzles: Install water rings at the nozzles to suppress dust flying by spraying water.

5. Wear protective equipment: Construction workers wear effective dust masks, goggles and other protective equipment.

6. Humidification of raw materials: Appropriately humidify the aggregates before mixing to reduce the generation of dust.

Types, functions and construction considerations of tunnel lining

Tunnel lining is a key technology in tunnel engineering. It is not only related to the structural safety of the tunnel, but also directly affects the service life and operational efficiency of the tunnel. The main function of tunnel lining is to support the surrounding rock and prevent the deformation and collapse of the surrounding rock. At the same time, it can also play a role in waterproofing and anti-seepage, ensuring the dryness and safety of the tunnel.

Types of tunnel lining

Tunnel lining can be mainly divided into the following types according to its construction method and structural characteristics:

1. Sprayed concrete lining: This is a fast and flexible construction method suitable for tunnel construction under various geological conditions. By spraying high-pressure concrete onto the surface of the tunnel surrounding rock, a protective layer is formed, which can quickly seal the surrounding rock and prevent further deformation of the surrounding rock.

2. Cast concrete lining: After the tunnel excavation is completed, concrete is poured using a formwork to form a lining with a more stable structure and better waterproof performance. The thickness and strength of this lining can be designed according to the specific needs of the tunnel.

3. Prefabricated assembled lining: Prefabricated concrete blocks or steel plates are produced in the factory and then transported to the tunnel site for assembly. This type of lining has a fast construction speed and is easy to control in quality, but the cost is relatively high.

4. Composite lining: Combining the characteristics of shotcrete and cast concrete, a layer of concrete is first sprayed as the initial support, and cast concrete is poured after the surrounding rock is stable to form a composite lining. This lining can better adapt to the deformation of the surrounding rock and improve the safety and stability of the tunnel.

The role of tunnel lining

The role of tunnel lining mainly includes:

Bearing loads such as surrounding rock pressure and groundwater pressure to ensure the stability and safety of the tunnel structure.

Preventing weathering, loosening and collapse of surrounding rocks, and reducing deformation of surrounding rocks around the tunnel.

Preventing groundwater infiltration and maintaining a dry environment inside the tunnel.

There are many types of tunnel linings, such as integral linings and composite linings. Their design and construction need to be comprehensively considered based on factors such as the geological conditions and use requirements of the tunnel.

Construction considerations for tunnel lining

The design of tunnel lining needs to comprehensively consider factors such as geological conditions, tunnel size, and use functions. During the construction process, the concrete mix ratio, pouring speed and maintenance conditions should be strictly controlled to ensure the quality of the lining. At the same time, it is also necessary to regularly inspect and maintain the tunnel lining to promptly detect and deal with problems such as lining cracks and water seepage to ensure the long-term safe operation of the tunnel.

Rock drilling rig, a powerful tool for drilling blasting holes in underground mining and tunnel construction

In the field of underground mining and tunnel construction, efficient drilling techniques are key to project progress and safety. As an important innovation in this field, rock drilling rigs have become indispensable equipment in underground engineering due to their excellent performance and adaptability. This article will delve into the design concept, working principle, technical advantages, and application of rock drilling rigs in modern underground construction.

Design concept and working principle

The design concept of rock drilling rig originates from a profound understanding of the complex underground environment. They are usually equipped with high-precision drilling systems and powerful power systems, which can quickly and accurately drill blast holes in various rocks. During operation, the trolley precisely controls the position and angle of the drill bit through advanced positioning systems and drilling arm adjustments, ensuring that the depth and direction of the borehole meet engineering requirements. At the same time, the trolley is also equipped with efficient dust removal and cooling systems to protect the normal operation of equipment in harsh environments.

Technical advantages

1. High efficiency and accuracy: Compared with traditional manual drilling, rock drilling rigs can complete drilling tasks at higher speed and accuracy, greatly improving the efficiency of underground construction.

2. Safety and Environmental Protection: Automated operations reduce personnel exposure to hazardous environments, while efficient dust removal systems reduce dust pollution and have minimal impact on the environment.

3. Flexibility and adaptability: The rock drilling rig can adapt to various complex underground environments, including narrow tunnels and irregular rock structures, ensuring the smooth progress of the project.

4. Cost effectiveness: Although the initial investment is high, in the long run, the rock drilling rig can save a lot of costs for the project by improving efficiency and reducing labor requirements.

Modern applications

The application of rock drilling rigs is becoming increasingly widespread in modern underground mining and tunnel construction. Whether it is the mining of metal mines or the excavation of highways and railway tunnels, their presence can be seen. Through precise drilling of blasting holes, the rock drilling rig provides a solid foundation for subsequent blasting operations, ensuring the safety and progress of the project.

The rock drilling rig has become an indispensable and efficient drilling tool in underground engineering due to its unique design, excellent performance, and wide application. With the continuous advancement of technology, future rock drilling rigs will become more intelligent and environmentally friendly, providing stronger support for the rapid development of underground engineering.